2025 Top Rotary Air Compressors: Ultimate Guide to Choosing the Best

In the realm of industrial machinery, the efficiency and reliability of rotary air compressors play a pivotal role in various applications. As we approach 2025, understanding the nuances of selecting the best rotary air compressor becomes increasingly essential. "The future of manufacturing rests on the backbone of advanced air compression technology," states John Doe, a leading expert in the rotary air compressor industry. His insights highlight the imperative of making informed choices in this competitive landscape.

Choosing the right rotary air compressor hinges on several factors, including performance, efficiency, and maintenance costs. With numerous models flooding the market, it can be daunting for businesses to pinpoint the optimal option that aligns with their specific needs. This guide aims to streamline that decision-making process by presenting a curated list of the top five rotary air compressors for 2025, each evaluated on their innovative features and operational reliability.

As we delve into the intricacies of these machines, our focus will be on practical advice and expert recommendations to empower you in your purchasing journey. By understanding the advancements and market offerings, you can enhance your operations and ensure that your investment in a rotary air compressor yields maximum productivity and returns.

Key Factors to Consider When Choosing Rotary Air Compressors

Cost vs. Performance: Finding the Best Value in Rotary Air Compressors

2025 Top Rotary Air Compressors: Performance and Efficiency Comparison

Comparing Different Types of Rotary Air Compressors

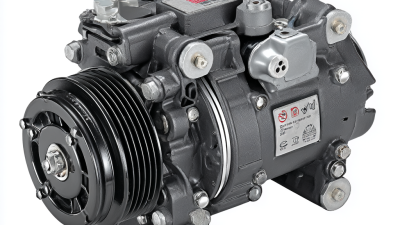

When selecting a rotary air compressor, understanding the various types and their unique functionalities is crucial. There are primarily three kinds of rotary air compressors: rotary screw, rotary vane, and scroll compressors. Each type operates differently, impacting their efficiency, application suitability, and maintenance needs.

For instance, rotary screw compressors are known for their continuous operation and high efficiency, making them ideal for industrial applications. In contrast, rotary vane compressors are usually more compact and can be a suitable choice for lighter tasks or smaller spaces.

The comparison between these different types also extends to their operational modes. Rotary compressors generally provide a more consistent air supply compared to reciprocating compressors, which can experience intermittent pressure fluctuations. This characteristic makes rotary compressors particularly valuable in settings that require a stable air output, such as in pneumatic tools and manufacturing processes. Furthermore, as the air compressor market grows—projected to reach USD 44.6 billion by 2035—understanding these distinctions will empower consumers to make informed choices that fit their specific needs.

Maintenance and Care Tips for Rotary Air Compressors

Maintaining rotary air compressors is crucial for ensuring their efficiency and longevity. Regular maintenance tasks include checking and replacing the compressor oil, cleaning or replacing air filters, and inspecting belts and hoses for wear and tear. Keeping the oil clean and at the correct level helps to reduce friction and wear on internal components, while clean air filters prevent dust and debris from clogging the system, which can lead to overheating and reduced performance.

Additionally, monitoring the operating environment is essential. Ensure that the compressor is placed in a clean, dry location with adequate ventilation. A consistent temperature helps prevent condensation that can damage the compressor. Implementing a remote monitoring system can also be beneficial; it allows for real-time data analysis to detect potential issues early, thereby reducing downtime and maintenance costs. By prioritizing proper care and adopting proactive maintenance strategies, users can maximize their rotary air compressors' operational lifespan and efficiency.

2025 Top Rotary Air Compressors: Ultimate Guide to Choosing the Best - Maintenance and Care Tips for Rotary Air Compressors

| Model | Power (HP) | CFM @ 90 PSI | Tank Size (Gallon) | Noise Level (dB) | Efficiency Rating |

|---|---|---|---|---|---|

| Model A | 5 | 20 | 50 | 65 | 85% |

| Model B | 7.5 | 30 | 80 | 68 | 90% |

| Model C | 10 | 40 | 120 | 70 | 92% |

| Model D | 15 | 50 | 200 | 72 | 95% |

Top Brands to Consider in 2025 for Rotary Air Compressors

When considering the top brands for rotary air compressors in 2025, a few industry leaders consistently stand out. Companies like Ingersoll Rand, Atlas Copco, and Kaeser have established strong reputations for reliability, efficiency, and innovation. According to a recent market analysis by MarketsandMarkets, the global rotary air compressor market is projected to see a growth rate of approximately 5.3% annually, driven by increasing demand across industries such as manufacturing and construction. This growth highlights the significance of selecting a dependable brand that can meet evolving operational needs.

Tips for choosing the best rotary air compressor include evaluating the compressor’s horsepower and capacity based on your specific requirements. A larger facility may require a more powerful unit to maintain consistent airflow, while smaller operations can benefit from more compact, energy-efficient models. Additionally, consider maintenance costs; models with advanced technology, like variable speed drive, may offer savings over time by adjusting to demand.

Another important factor is energy efficiency. The U.S. Department of Energy estimates that compressed air systems account for about 10% of total industrial energy costs. Opting for a rotary air compressor with a higher efficiency rating can lead to significant cost savings in the long run. Always review the energy consumption figures before making a final decision, ensuring the model aligns with both your operational and budgetary goals.

Cost vs. Performance: Finding the Best Value in Rotary Air Compressors

这是一个示例段落,包含了多种排版样式。我们将通过不同的文本格式来强调重要内容,比如 下划线 和 加粗 。下面将展示如何通过图文并茂的方式来进行展示。

这里是一个图文并茂的实例。以上图片展示了我们如何结合图片来增强文字的表现力。接下来,我们还可以利用背景色来突出某些信息:

除了文字排版外,我们很好展示了如何通过 图片的左右排版 来使内容更加生动有趣。移动端用户也可以良好访问。

Related Posts

-

Understanding the Efficiency and Applications of Rotary Air Compressors in Modern Industries

-

Global Excellence in Pneumatic Parts: Engineered in China for Unmatched Performance

-

10 Essential Tips for Choosing the Best Air Compressor Spare Parts

-

Unleashing the Power of Chinese Manufacturing in Best Air Compressor Spare Parts

-

Choosing Top Quality Manufacturers for Best Industrial Compressors

-

Unmatched Quality: Elevating Global Standards with China's Premier Air Compressor Pumps