2025 Top Screw Compressors: Key Features and Benefits You Need to Know

As industries continue to evolve, the demand for efficient and reliable machinery has grown significantly, particularly in the realm of air compression. Among the various types of air compressors available, screw compressors stand out due to their superior performance and durability. The 2025 Top Screw Compressors encompass a range of innovative features and advantages that cater to diverse industrial applications, making them an essential consideration for businesses looking to enhance productivity and reduce operational costs.

Screw compressors utilize a distinctive rotary design that allows for continuous air compression, translating into greater efficiency and lower energy consumption compared to traditional piston compressors. Their ability to deliver a constant flow of compressed air makes them ideal for processes requiring stable pressure and volume. Additionally, advancements in technology have led to the development of models that are quieter, more compact, and easier to maintain, further solidifying their position as the preferred choice in various sectors.

Understanding the key features and benefits of 2025's top screw compressors is crucial for making informed decisions when selecting equipment for your operations. This overview aims to highlight those essential elements, providing insight into how these compressors can not only meet the demands of today's industries but also pave the way for a more sustainable future in air compression technology.

Key Characteristics of 2025 Top Screw Compressors

When evaluating the top screw compressors of 2025, it’s essential to focus on their key characteristics that set them apart in the industrial landscape. One significant feature is their advanced energy efficiency, which is largely achieved through innovative designs and intelligent control systems. These compressors are engineered to minimize energy consumption while maximizing output, making them an economically viable choice for businesses aiming to reduce operational costs. Additionally, their ability to operate effectively in a variety of environments enhances their appeal, allowing them to perform reliably in both heavy-duty and light-duty applications.

Another notable characteristic is the improved performance and durability offered by the latest screw compressor models. They are constructed with high-quality materials that resist wear and tear, ensuring a longer lifespan and lower maintenance requirements. Furthermore, many of these compressors incorporate noise-reduction technologies, providing quieter operation compared to earlier models. This is particularly beneficial for industries that need to maintain a low noise level in their working environments. Enhanced monitoring and diagnostic features are also prevalent, allowing operators to oversee performance metrics in real time and proactively address any potential issues before they escalate.

2025 Top Screw Compressors: Key Features and Benefits You Need to Know - Key Characteristics of 2025 Top Screw Compressors

| Feature | Description | Benefits |

|---|---|---|

| High Efficiency | Designed with advanced rotor profiles to optimize airflow | Reduces energy consumption and operational costs |

| Compact Design | Small footprint while maintaining high output | Saves space in installations and allows for flexible positioning |

| Low Noise Operation | Engineered for quiet functionality | Ideal for environments where noise reduction is critical |

| Smart Control Systems | Integrated electronic controls for optimized performance | Improves process efficiency and provides data analytics |

| Durability | Constructed with high-quality materials for extended lifespan | Reduces the frequency of maintenance and downtime |

Performance Advantages of Modern Screw Compressors

Modern screw compressors have gained significant traction in various industrial applications due to their efficiency and reliability. One of the standout performance advantages of these compressors is their ability to operate continuously for extended periods. According to the International Journal of Refrigeration, modern screw compressors can achieve efficiency levels exceeding 90%, which is substantially higher than traditional reciprocating compressors. This efficiency translates into reduced energy costs and lower carbon emissions, making screw compressors an environmentally friendly choice.

Another notable benefit of screw compressors is their adaptability to varying load conditions. With the integration of advanced control systems, modern models can adjust their output to match real-time demand. This dynamic capability helps maintain optimal performance without the waste associated with overproduction. Additionally, a report from the Energy Department highlights that the use of variable speed drive technology in screw compressors can provide energy savings of up to 30% compared to fixed-speed models.

Tips: When considering the right screw compressor for your operation, evaluate the specific requirements of your processes, including pressure needs and ambient conditions. Regular maintenance is crucial for maximizing the lifespan and efficiency of these compressors, so invest in a robust maintenance program to ensure peak performance throughout their operational life.

Energy Efficiency Trends in 2025 Compressor Models

In 2025, the trend towards energy efficiency in screw compressors is set to become a leading factor in equipment selection across various industries. Recent industry reports suggest that advancements in technology can improve energy efficiency by as much as 30% compared to previous models. These innovations often include the integration of variable speed drives, which allow compressors to adjust their output to match the demand of the system. This capability not only reduces energy consumption but also minimizes wear and tear on the equipment, extending its lifecycle and reducing maintenance costs.

Another significant trend is the development of smart compressors equipped with IoT technology. These models can monitor performance in real-time, providing operators with crucial data that helps optimize energy use. Reports from energy efficiency organizations indicate that facilities that implement smart technology can achieve savings of up to 20% on energy costs. Furthermore, zero oil technology is gaining traction, enhancing oil recovery processes and resulting in lower energy requirements for operation. The shift towards energy-efficient screw compressors not only contributes to operational cost savings but also aligns with global sustainability goals, as industries are increasingly held accountable for their environmental impact.

Technological Innovations Driving Screw Compressor Development

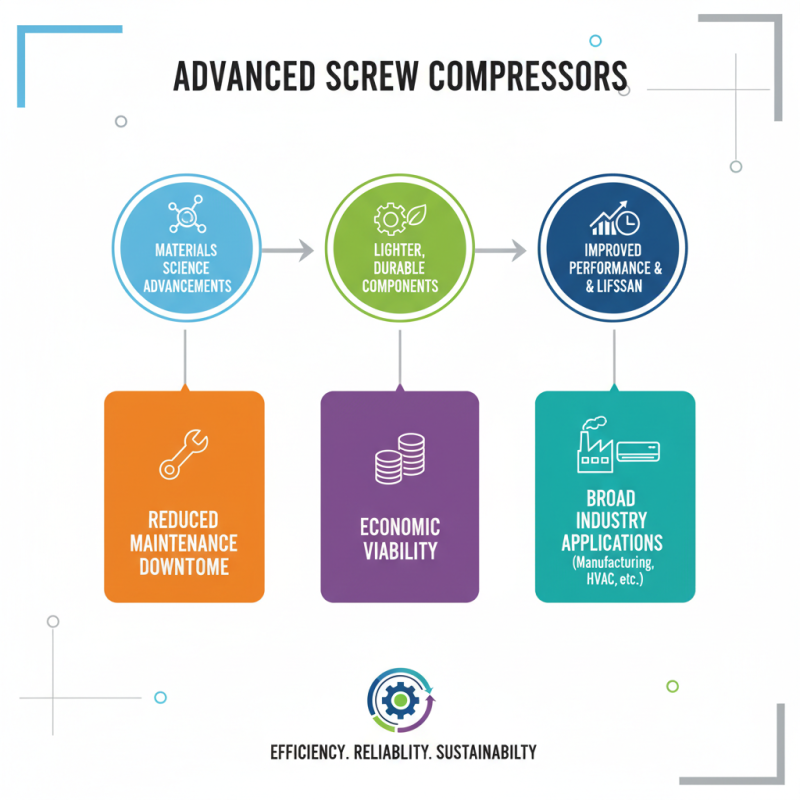

The development of screw compressors has been significantly influenced by technological innovations that enhance efficiency, reliability, and environmental sustainability. With advances in materials science, manufacturers are now able to produce lighter and more durable components that improve the performance of screw compressors. This not only increases their lifespan but also reduces downtime for maintenance, making them more economically viable for industries ranging from manufacturing to HVAC systems.

Moreover, digital technologies such as IoT and AI integration have transformed the operational capabilities of screw compressors. These innovations enable real-time monitoring and analytics, allowing operators to optimize performance and preemptively address potential issues before they lead to failures. Enhanced control systems equipped with predictive algorithms ensure that compressors operate at peak efficiency while minimizing energy consumption and emissions. This shift towards smarter, data-driven solutions is redefining the standards for energy efficiency and operational excellence in screw compressor technology, making them an indispensable asset in modern industrial applications.

Applications and Industries Benefiting from Screw Compressors

Screw compressors are versatile machines that play a crucial role in various industries, harnessing their efficiency and reliability in numerous applications. One notable application is in the refrigeration and air conditioning sector, where these compressors are vital for maintaining optimal temperature and humidity levels. Their ability to provide a continuous supply of compressed air makes them ideal for food processing and storage, where maintaining freshness and preventing spoilage is paramount.

In addition to refrigeration, screw compressors are extensively utilized in the manufacturing and chemical industries, where consistent and high-quality compressed air is essential for powering pneumatic tools and equipment. Their energy efficiency and reduced maintenance requirements also make them a preferred choice for operations in industries such as pharmaceuticals, textiles, and construction. By delivering stable pressure and flow, screw compressors significantly enhance productivity and operational reliability across these sectors, ensuring that processes run smoothly and efficiently.

Applications and Industries Benefiting from Screw Compressors

Related Posts

-

Benefits of Choosing the Best Screw Compressors for Your Business Needs

-

Choosing Top Quality Manufacturers for Best Industrial Compressors

-

Unlocking Efficiency: The Advantages of Choosing Industrial Compressors for Your Business

-

7 Essential Tips for Choosing the Right Air Compressors for Your Business

-

The Ultimate Guide to Understanding Screw Air Compressors and Their Benefits

-

Finding Quality Suppliers for Best Air Dryers with Industry Insights and Data