Advantages of Using Scroll Compressors in Modern Applications

In recent years, the demand for energy-efficient and reliable cooling solutions has surged, prompting a significant shift in the HVAC and refrigeration industries. One of the most innovative technologies that have emerged to meet these needs is the scroll compressor. Renowned for their compact design and enhanced performance characteristics, scroll compressors are rapidly becoming the preferred choice for modern applications ranging from residential air conditioning systems to large-scale industrial refrigeration units. This blog will explore the numerous advantages of using scroll compressors, including their high efficiency, low noise levels, and durability, which position them as a critical component for the future of climate control and cooling technologies. By understanding the benefits of scroll compressors, stakeholders can make informed decisions that not only enhance operational performance but also contribute to a more sustainable and environmentally friendly future.

Benefits of Enhanced Energy Efficiency in Scroll Compressors Across Industries

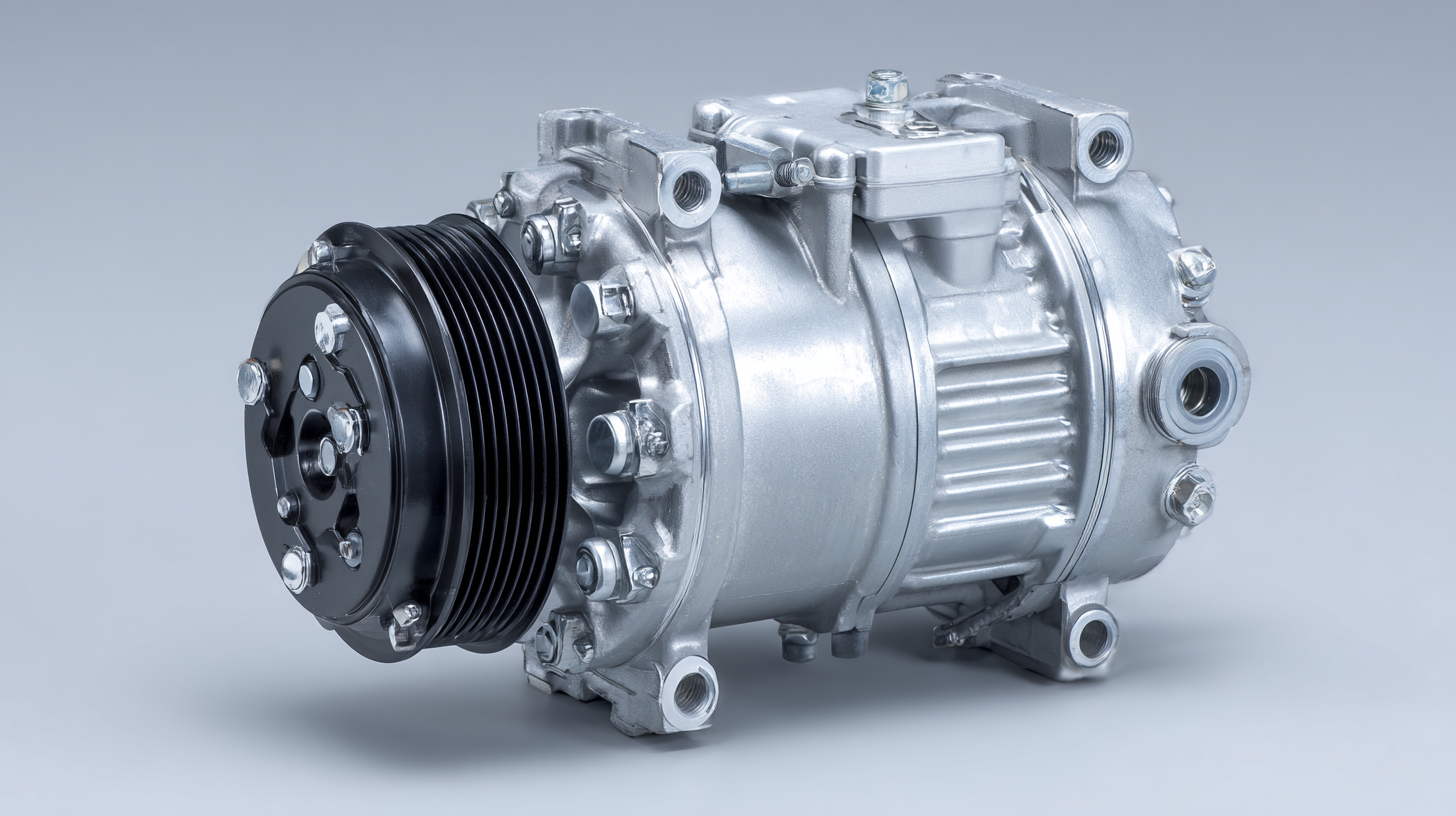

Scroll compressors have gained prominence across various industries due to their exceptional energy efficiency. Unlike traditional reciprocating compressors, scroll compressors operate on a simple, yet effective mechanism that significantly reduces energy consumption. This efficiency translates into lower operating costs, making them an attractive choice for businesses looking to enhance their sustainability efforts while optimizing performance.

In addition to energy savings, scroll compressors also contribute to a more consistent and reliable operation. Their design minimizes vibration and noise, leading to a more pleasant working environment. This is especially beneficial in commercial applications, such as refrigeration and HVAC systems, where silent operation can enhance customer experiences. Moreover, the reduced wear and tear associated with scroll compressors means less frequent maintenance and longer service life, ultimately resulting in lower total cost of ownership for companies across diverse sectors.

Impact of Lower Noise Levels on Workplace and Residential Environments with Scroll Technology

Scroll compressors have gained popularity in various modern applications, particularly due to their ability to operate quietly. The impact of lower noise levels, especially in workplace and residential environments, cannot be overstated. Traditional compressors often generate disruptive sounds that can hinder productivity and overall comfort. In contrast, scroll technology employs a unique design that minimizes vibrations and reduces noise emissions, creating a more serene atmosphere.

In workplaces, a quieter environment fosters better concentration and enhances employee morale. When employees are not distracted by loud machinery, they can focus more on their tasks, leading to increased efficiency. Similarly, in residential settings, lower noise levels contribute to a more peaceful living experience. Families can enjoy conversations, watch television, or relax without the interruption of compressor noise. This is especially crucial in urban areas where sound pollution is already a concern. Overall, the advantages of using scroll compressors extend beyond energy efficiency, significantly enhancing the quality of life in both professional and personal spaces.

Advantages of Using Scroll Compressors in Modern Applications

This bar chart illustrates the impact of lower noise levels achieved through scroll compressor technology in various environments, highlighting the significant improvements in workplace and residential settings.

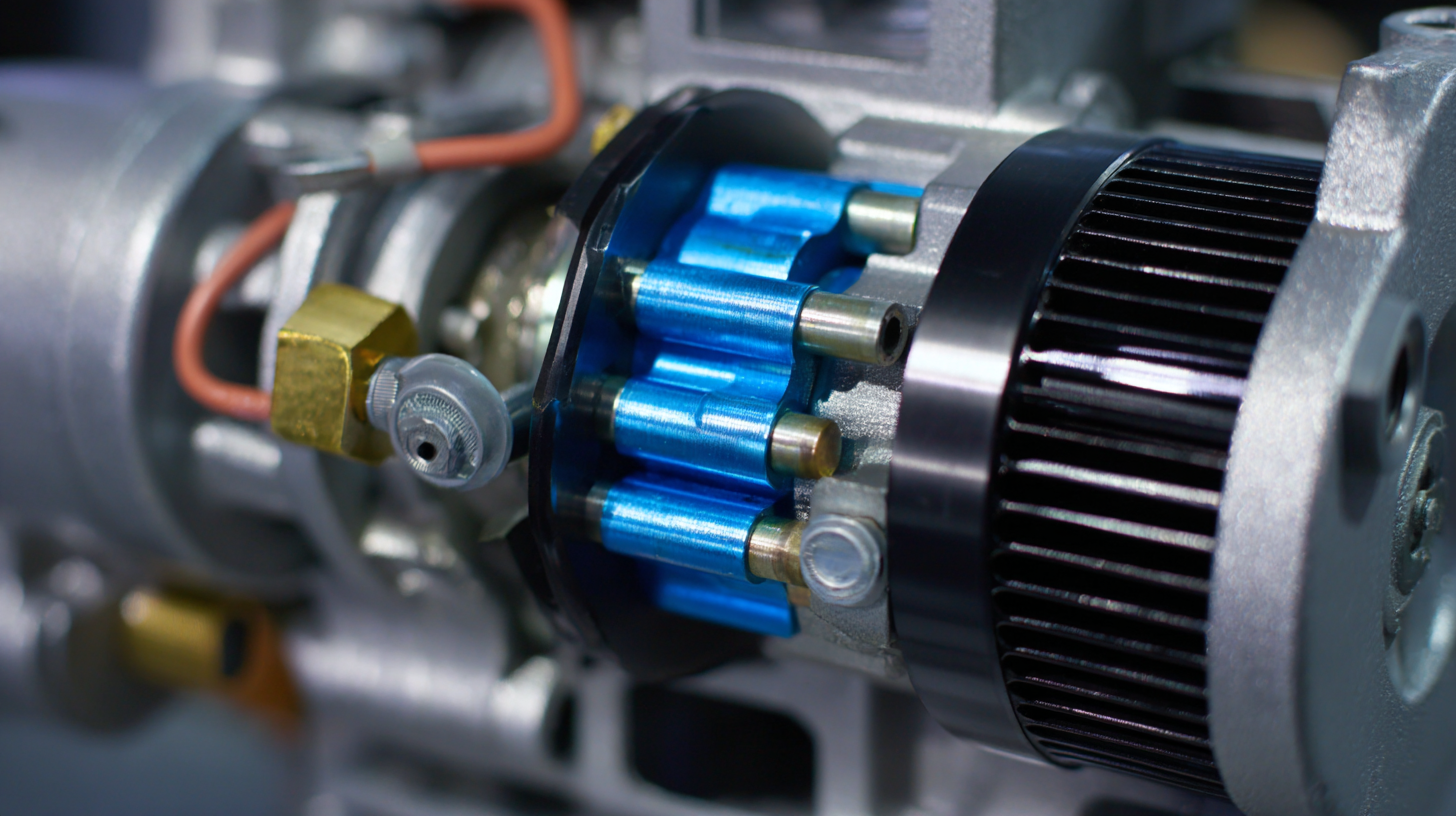

Comparative Analysis: Scroll Compressors vs. Traditional Reciprocating Compressors for Reliability

When comparing scroll compressors to traditional reciprocating compressors, one of the most notable differences is in reliability. Scroll compressors operate using two interleaved spiral elements, which significantly reduces the number of moving parts compared to the piston-driven mechanics of reciprocating compressors. This reduction in complexity leads to decreased wear and tear, resulting in longer service life and lower maintenance requirements. Additionally, the continuous flow nature of scroll compressors minimizes the pulsations in the refrigerant flow, further enhancing system stability and reliability.

Another key advantage of scroll compressors lies in their efficiency during operation. The design allows for smoother and quieter performance, reducing vibrational stress that often contributes to mechanical failures in reciprocating compressors. This smoother operation not only translates to higher efficiency in energy usage but also leads to a quieter environment, which is particularly valuable in residential and commercial applications where noise is a concern. Overall, the comparative analysis highlights that for modern applications requiring reliability, scroll compressors present a stronger case than their traditional counterparts.

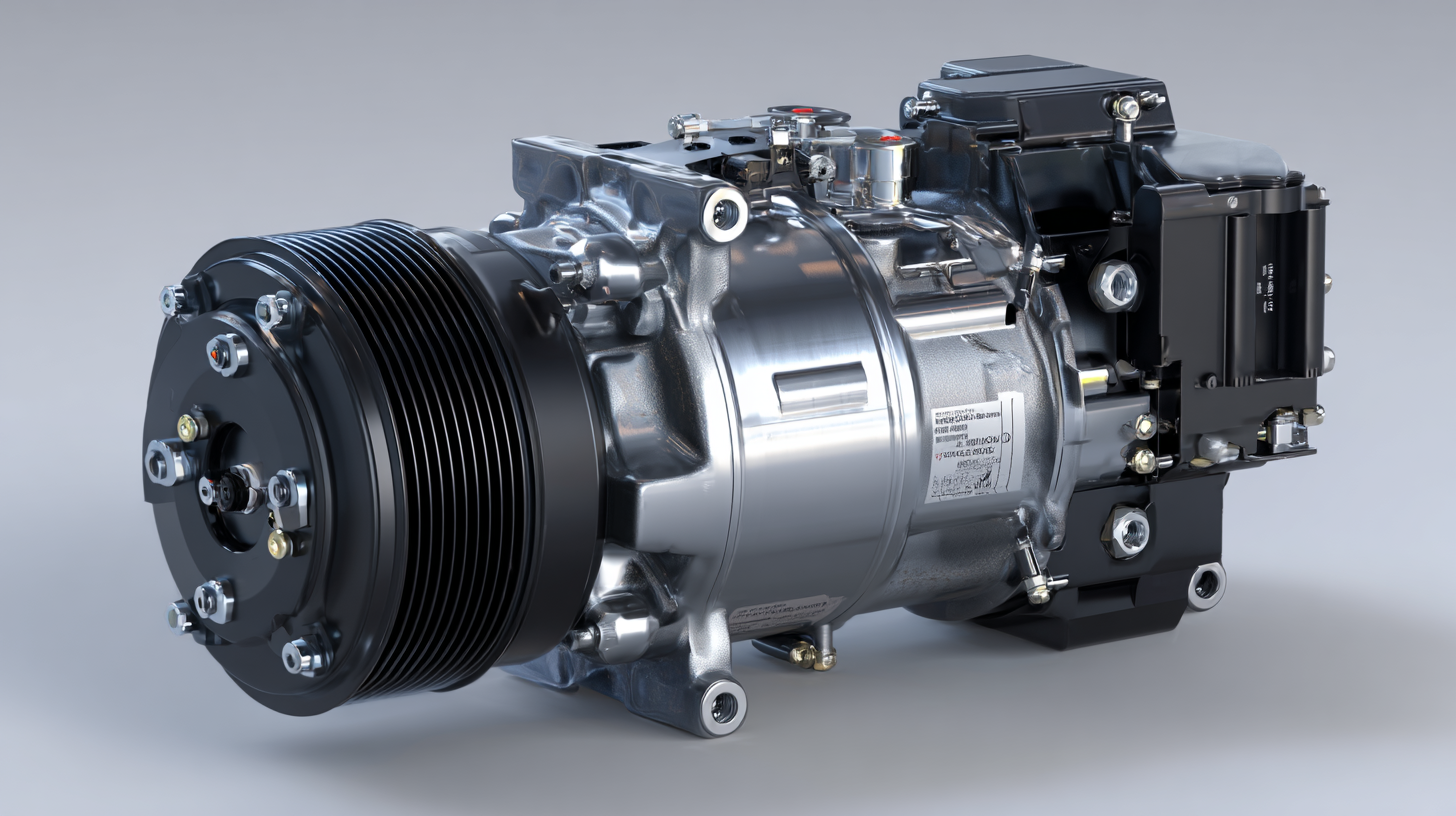

The Role of Compact Design in Optimizing Space and Installation Costs for Modern Applications

In the era of efficient energy usage and cost optimization, scroll compressors have emerged as a key player in modern applications. Their compact design significantly contributes to optimizing both space and installation costs, making them an ideal choice for various sectors, including HVAC, refrigeration, and manufacturing. According to a report by the International Society of Automation, the space-saving aspect of scroll compressors allows for up to 30% more usable space within installations compared to traditional compressor types. This is particularly beneficial in urban environments where real estate is at a premium.

Moreover, the streamlined installation process facilitated by the compact design of scroll compressors can lead to reduced labor costs. A recent analysis from the Compressor Manufacturers Association indicated that installations using scroll compressors can cut installation time by nearly 25%, translating into significant savings for businesses. Additionally, the lightweight nature of these compressors minimizes the structural support required, further lowering costs involved in the overall installation. As industries strive for greater efficiency and reduced operational expenses, the adoption of scroll compressors is proving to be a strategic choice for modern applications.

Case Studies: Real-World Performance Metrics of Scroll Compressors in HVAC Systems

Scroll compressors have gained significant traction in HVAC applications due to their efficiency and reliability. A recent case study conducted on a commercial building's cooling system revealed a 30% reduction in energy consumption compared to traditional reciprocating compressors. This was attributed to the scroll compressor's ability to operate continuously at optimal efficiency, minimizing energy loss during cycles. Additionally, the quieter operation of scroll compressors significantly improved the indoor environment, making them ideal for settings where noise is a concern, such as offices and healthcare facilities.

Another compelling case study highlights the performance of scroll compressors in a medium-sized industrial application. The implementation resulted in a substantial decrease in maintenance costs, as the fewer moving parts reduce the wear and tear typically seen in alternative compressor technologies. With an extended operational life and reduced need for repairs, the total cost of ownership of the HVAC system was lowered. These metrics not only underscore the operational advantages of scroll compressors but also reflect their value in promoting sustainability through enhanced energy efficiency and reduced carbon footprints in modern applications.

Advantages of Using Scroll Compressors in Modern Applications - Case Studies: Real-World Performance Metrics of Scroll Compressors in HVAC Systems

| Application | Energy Efficiency (SEER) | Cooling Capacity (BTU/h) | Noise Level (dB) | Operating Cost ($/year) | Maintenance Frequency (years) |

|---|---|---|---|---|---|

| Residential Cooling | 18.5 | 24000 | 57 | 150 | 2 |

| Commercial HVAC | 16.0 | 50000 | 60 | 300 | 3 |

| Industrial Refrigeration | 15.5 | 80000 | 65 | 500 | 4 |

| Chilled Water Systems | 17.0 | 30000 | 59 | 250 | 3 |