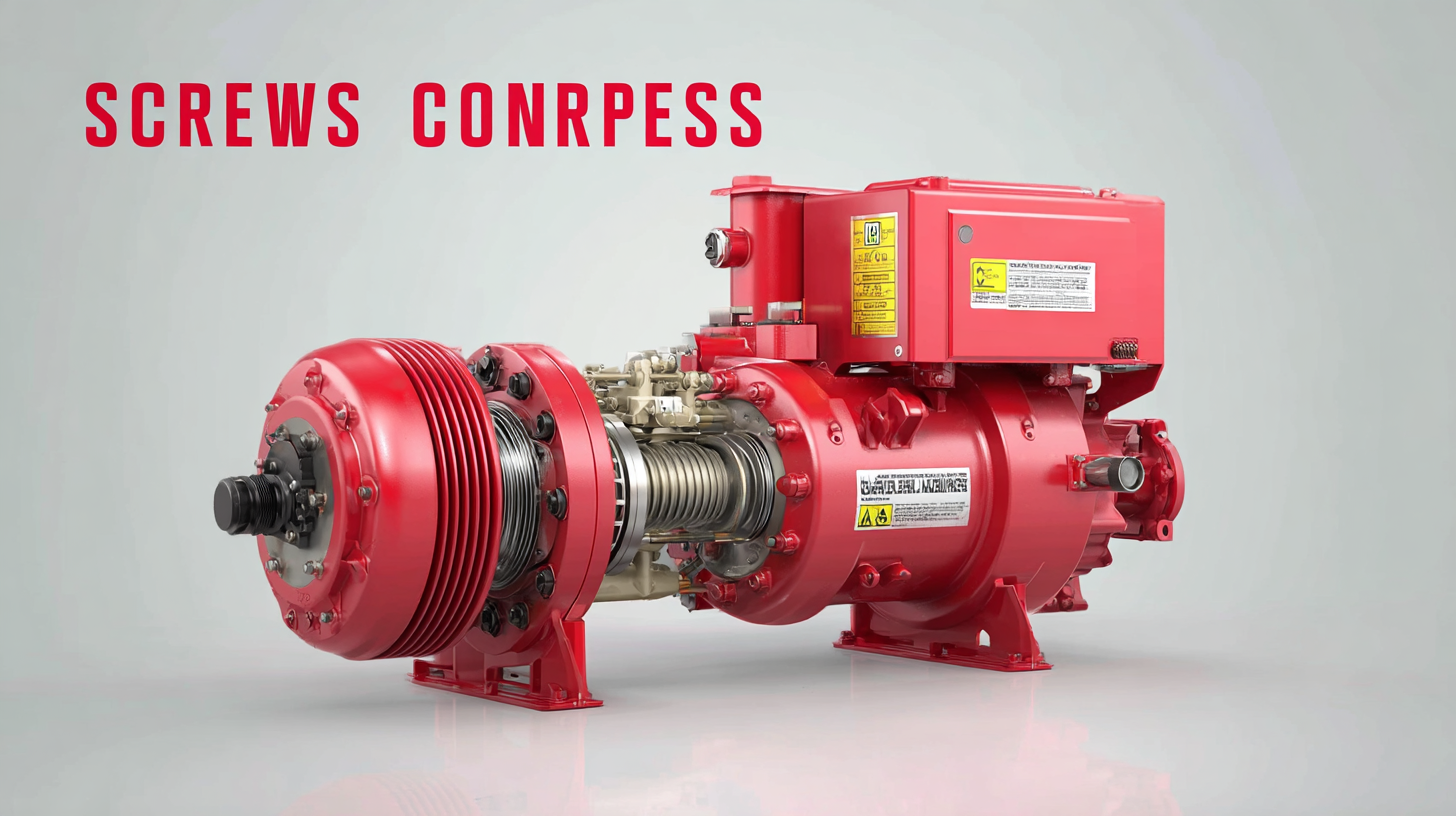

Benefits of Choosing the Best Screw Compressors for Your Business Needs

In today's competitive industrial landscape, the choice of equipment can significantly impact operational efficiency and cost-effectiveness. Screw compressors, renowned for their reliability and energy efficiency, are increasingly being recognized as a vital component in many businesses. According to a report by Market Research Future, the global screw compressor market is projected to grow at a CAGR of 4.2% from 2020 to 2025, highlighting their rising demand across various sectors. These compressors offer several advantages, including reduced energy consumption and lower maintenance costs, making them an ideal choice for companies aiming to optimize their operations. As we explore the benefits of screw compressors further, it is essential to consider the forthcoming technological advancements that will shape their performance and efficiency in the coming years.

Key Factors Influencing the Performance of Screw Compressors in Industrial Applications

When selecting screw compressors for industrial applications, understanding the key factors influencing their performance is crucial. One of the most significant aspects to consider is the compressor's design and configuration. The rotor profile, for instance, plays a vital role in determining the efficiency and reliability of the compressor. Well-designed rotors can enhance airflow and reduce energy consumption, ultimately impacting operational costs and productivity.

Another critical factor is the operating environment. Screw compressors, unlike reciprocating compressors, perform optimally under consistent load and temperature conditions. It's essential to evaluate the specific conditions in which the compressor will operate, including humidity and ambient temperature, as these can directly affect the longevity and efficiency of the unit. Additionally, regular maintenance and the use of appropriate lubricants significantly influence performance, ensuring the compressor runs smoothly and prolonging its lifespan. By focusing on these key factors, businesses can select the best screw compressors tailored to their industrial needs, leading to improved efficiency and cost savings.

Benefits of Choosing the Best Screw Compressors for Your Business Needs

| Dimension | Description | Impact on Performance |

|---|---|---|

| Energy Efficiency | The ability of the compressor to minimize energy consumption during operation. | Higher energy efficiency reduces operational costs significantly. |

| Noise Levels | The amount of noise produced during compressor operation, usually measured in dB(A). | Lower noise levels contribute to a better working environment. |

| Maintenance Needs | The frequency and complexity of maintenance required for optimal operation. | Reduced maintenance needs lead to less downtime and lower maintenance costs. |

| Pressure Stability | The ability to maintain consistent pressure levels during operation. | Consistent pressure enhances productivity in industrial applications. |

| Durability | The longevity of the equipment under different operating conditions. | Higher durability reduces the frequency of replacement and associated costs. |

| Size & Portability | The physical dimensions and weight of the compressor. | Compact and portable designs allow for flexible installation and easy relocation. |

The Impact of Energy Efficiency Ratings on Long-term Operational Costs of Screw Compressors

In recent years, the importance of energy efficiency in screw compressors has grown significantly due to its direct impact on long-term operational costs. According to a market research report, the global screw compressor market is expected to expand from $12.74 billion in 2025 to $16.30 billion by 2030, indicating a compound annual growth rate (CAGR) of around 5.6%. This growth is largely attributed to the increasing demand for energy-efficient solutions in various industries, as businesses seek to minimize energy consumption and reduce their overall operating expenses.

Furthermore, the Global Air Compressor Rental Market is projected to reach $8,221.1 million by 2033, growing at a CAGR of 6.8%. This trend underscores the rising preference for energy-saving technologies that enhance productivity while ensuring lower energy costs. Companies investing in high-efficiency screw compressors not only boost their operational effectiveness but also contribute to sustainability goals by reducing carbon footprints.

With advancements in technology, modern screw compressors are designed to achieve higher efficiency ratings, making them a vital asset for businesses aiming to optimize their operational costs over the long term.

Comparative Analysis of Screw Compressors: Cost-Effectiveness vs. Maintenance Needs

When selecting a screw compressor for your business, a comparative analysis of cost-effectiveness versus maintenance needs is crucial. On one hand, cost-effectiveness focuses on initial purchase prices and operating efficiency. Businesses often seek models that offer lower energy consumption, which contributes to reduced long-term operational costs. However, it’s essential not to overlook the importance of maintenance. A compressor that is initially cheaper but requires frequent repairs can lead to higher overall expenses.

To make an informed decision, consider investing in screw compressors from reputable manufacturers known for their durability. Regular maintenance is key to prolonging the life of your equipment. Implement a maintenance schedule that includes routine checks and service by qualified technicians. This proactive approach can prevent unexpected breakdowns that disrupt operations and incur additional costs.

Additionally, examine the total cost of ownership, which encompasses not only purchase price and energy consumption but also maintenance needs over time. A more expensive screw compressor may offer superior reliability and lower maintenance requirements, ultimately proving to be the more cost-effective option in the long run. By taking these factors into account, you can ensure your investment aligns with your business needs while maximizing efficiency and performance.

Understanding the Role of Noise Levels in Choosing the Right Screw Compressor for Your Business

When selecting a screw compressor for your business, noise levels are a crucial factor that can significantly influence your operational environment. High noise levels from compressors can lead to discomfort for employees, potential hearing damage over time, and overall workplace dissatisfaction. Thus, it's essential to assess the decibel ratings of different models when making your decision. Opting for quieter, high-efficiency screw compressors not only promotes a better working atmosphere but also aligns with a growing commitment to sustainability and employee well-being.

In addition to employee comfort, lower noise levels can enhance your business’s public image, especially if you operate in a residential area or near other businesses. A quieter compressor can mitigate disturbances in the community, fostering better relationships and compliance with local regulations. Moreover, investing in advanced noise-reduction technologies may yield long-term benefits, including increased reliability and reduced maintenance costs. Businesses that prioritize both performance and noise levels when choosing screw compressors will find that they can boost productivity while creating a more pleasant environment for everyone involved.

Advancements in Screw Compressor Technology: Benefits for Modern Industrial Operations

Advancements in screw compressor technology have significantly transformed modern industrial operations, making them more efficient and reliable. According to a recent report from the International Institute of Compressed Air (IICA), the latest innovations in screw compressors can improve energy efficiency by up to 30%. This reduction in energy consumption not only lowers operational costs but also minimizes the environmental impact of industrial activities.

Moreover, modern screw compressors are equipped with advanced monitoring systems that provide real-time data on performance and maintenance needs. A 2022 industry survey highlighted that businesses utilizing smart compression technology experienced a 25% decrease in downtime and a 15% increase in overall productivity. By leveraging these advancements, companies can ensure that their operations run smoothly, allowing them to allocate resources more effectively and focus on core business growth. As industries continue to evolve, investing in the best screw compressors becomes essential to maintaining a competitive edge and meeting the demands of today’s market.

Benefits of Choosing the Best Screw Compressors for Your Business Needs

This bar chart illustrates the advantages of modern screw compressors based on their efficiency, energy savings, maintenance costs, and operational reliability.