5 Best Screw Compressor Parts You Should Invest In

In the realm of industrial and commercial applications, screw compressors play a vital role in providing reliable and efficient air pressure solutions. Understanding the significance of quality screw compressor parts can greatly enhance the performance and longevity of these machines. Investing in the right components not only ensures optimal functionality but also helps in minimizing maintenance costs and downtime. As we explore the five best screw compressor parts you should consider, we will delve into how these essential elements contribute to the overall efficiency and reliability of your compressor system. Whether you are looking to upgrade existing equipment or planning a new installation, knowing which screw compressor parts hold the most value will empower you to make informed decisions for future operations.

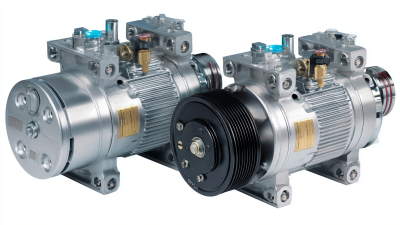

Essential Components for Optimal Screw Compressor Performance

Screw compressors are essential for various industrial applications, requiring specific components for optimal performance. Investing in high-quality parts not only enhances efficiency but also extends the lifespan of the system. Key components include rotors, bearings, seals, and control systems. According to a recent report by the International Compressor Manufacturing Association, compressors fitted with advanced rotor designs can improve energy efficiency by up to 15%. This makes rotors a crucial investment for operators looking to reduce operational costs while maintaining productivity.

Tip: Regularly monitor rotor wear and performance. Early detection of irregularities can prevent costly downtime and ensure your compressor operates at peak efficiency.

Bearings and seals are equally vital for maintaining optimal pressure and preventing leaks. High-quality bearings can reduce friction and wear, while durable seals minimize air loss and protect internal components. Data from the American Society of Mechanical Engineers indicates that improperly maintained bearings can lead to a 25% increase in energy consumption. Therefore, it is essential to choose reliable bearings and seals designed for the specific demands of your operations.

Tip: Schedule routine maintenance checks for bearings and seals to retain compressor integrity, ensuring longevity and performance in your system.

Key Factors to Consider When Selecting Parts for Screw Compressors

When selecting parts for screw compressors, several key factors warrant consideration to ensure optimal performance and longevity of your equipment. The global market for oil-free screw compressors is projected to reach $3.99 billion by 2032, with a compound annual growth rate (CAGR) of 5.3% from 2025. This growth underlines the increasing demand for reliable and efficient compressor solutions, which highlights the importance of choosing parts that align with industry advancements.

One crucial tip is to prioritize compatibility with your existing systems. Ensure that the parts you select are designed to function seamlessly with your compressor's specifications. This can significantly reduce the risk of operational issues, leading to greater efficiency and lower maintenance costs. Additionally, consider the materials used in the parts; high-quality materials can enhance durability and performance.

Another important consideration is maintenance. A mindset focused on regular upkeep can lead to fewer breakdowns and thereby higher overall profits. Investing in parts that are easier to maintain can save time and costs in the long run. For instance, oil-free air compressors represent a growing segment in the market, noted for their cleanliness and reduced environmental impact, making them a favorable option in many sectors.

5 Best Screw Compressor Parts You Should Invest In

Top Brands and Their Innovative Offerings in Screw Compressor Components

When considering investment in screw compressor parts, understanding the innovative offerings from top brands is essential. Leading manufacturers have developed advanced components that enhance efficiency and reliability. For instance, companies like Atlas Copco and Ingersoll Rand are renowned for their high-performance rotors and airends, designed to optimize energy consumption while maximizing output. These innovations not only extend the lifespan of the compressor but also reduce maintenance costs significantly.

Tips for selecting the right components include evaluating the compatibility of parts with existing systems and considering the long-term operating costs. Investing in premium components may have upfront costs, but the potential savings in energy consumption and maintenance should not be overlooked. Additionally, always opt for genuine parts from reputable brands to ensure quality and performance, as counterfeit components can lead to costly downtime and repairs.

Another key aspect is the incorporation of smart technology in compressor parts. Brands like Boge are integrating IoT capabilities in their components, allowing for real-time monitoring and predictive maintenance. This technology can greatly enhance operational efficiency and reduce unforeseen breakdowns. By staying informed about the latest trends and technologies, businesses can make smarter investment decisions in their screw compressor components.

Maintaining Efficiency: Upgrades and Replacements for Screw Compressors

When it comes to maintaining the efficiency of screw compressors, investing in the right parts is crucial. Over time, certain components can wear out or become outdated, leading to decreased performance and higher operational costs. Upgrading elements such as rotors, seals, and oil filtration systems can significantly enhance the reliability and efficiency of your compressor setup. For instance, advanced sealing technologies can minimize leakage, while improved rotors can optimize air intake and compression rates, ultimately resulting in energy savings.

Additionally, integrating smart technologies can further elevate compressor performance. These innovations allow for real-time monitoring of system health, enabling predictive maintenance that reduces downtime and operational disruptions. Investing in these upgrades not only ensures optimal functionality but also helps to mitigate contamination risks associated with traditional compressor setups. Therefore, investing in high-quality screw compressor parts and modern technologies is essential for achieving sustained efficiency and reliability in your operations.

5 Best Screw Compressor Parts You Should Invest In - Maintaining Efficiency: Upgrades and Replacements for Screw Compressors

| Part Name | Description | Benefits | Replacement Frequency |

|---|---|---|---|

| Air End | The primary component that compresses air in the screw compressor. | Enhances efficiency, reduces energy consumption. | Every 8,000-12,000 operating hours |

| Filters | Components that remove impurities from the air and oil. | Improves air quality, extends component life. | Every 1,500-2,500 operating hours |

| Oil Separator | Separates oil from the compressed air stream. | Enhances performance, reduces oil carryover. | Every 6,000-8,000 operating hours |

| Cooling System | Maintains optimal operating temperatures. | Prevents overheating, sustains efficiency. | Inspect annually; replace as needed. |

| Drive Motor | Powers the screw compressor operation. | Critical for efficiency and performance. | Replace when performance declines or fails. |

Cost-Effective Solutions for Long-Term Screw Compressor Reliability

When it comes to maintaining the efficiency and reliability of screw compressors, investing in high-quality parts is essential. The right replacements not only enhance performance but also minimize downtime and repair costs in the long run. A well-maintained screw compressor can serve multiple industrial applications, emphasizing the importance of choosing parts that offer durability without breaking the bank.

Cost-effective solutions such as variable speed drive controllers and reliable airend assemblies can significantly improve energy efficiency and operational stability. Additionally, durable filters and separators play a critical role in maintaining air quality and preventing potential damage to the compressor system. Investing in these key components ensures that your screw compressor operates smoothly and efficiently, ultimately leading to significant savings and a longer lifespan for your system. By prioritizing quality and performance in these essential parts, businesses can achieve better productivity while keeping operational costs in check.

Related Posts

-

5 Reasons Best Screw Compressor Parts Enhance Your Operational Efficiency

-

Unlocking Efficiency with Best Rotary Screw Air Compressors Technical Specs and Buying Guide

-

Exploring Best Air Compressor Accessories for 2025 Technology Trends and How to Boost Efficiency

-

Ultimate Guide to Choosing the Best Air Compressor Accessories for Your Needs

-

7 Essential Tips for Selecting the Best Scroll Air Compressor for Your Needs

-

Ultimate Guide to Choosing the Best Piston Compressor for Your Needs