How to Choose the Best Air Compressor Pumps for Your Needs

Choosing the right air compressor pumps can be a daunting task, especially with the wide array of options available in the market today. As John Smith, a renowned expert in the field of pneumatic tools, once stated, "Selecting the perfect air compressor pump requires an understanding of both your specific application and the capabilities of the pump itself." This insight highlights the importance of matching your needs with the right equipment to achieve optimal performance.

In the world of air compressors, the pump is arguably the heart of the system. It's essential to consider factors such as the intended use, the required pressure and volume, and the space available for installation. Whether you are a DIY enthusiast or a professional contractor, choosing the right air compressor pumps can significantly influence your work efficiency and project outcomes. Understanding these nuances not only helps in making an informed decision but also ensures that your investment yields the best possible results for your specific applications.

As we delve deeper into the selection process, we will explore various types of air compressor pumps, their features, and practical tips to help you make the best choice tailored to your unique requirements. With the right information, you can navigate the complexities of the market and find the perfect air compressor pump that meets your needs.

Understanding Different Types of Air Compressor Pumps

When selecting the best air compressor pump for your needs, it's crucial to understand the various types available on the market.

Air compressor pumps primarily fall into two categories: reciprocating (or piston) pumps and rotary screw pumps. Reciprocating pumps are the most common type, offering high pressure and efficiency. They work by compressing air using a piston mechanism, making them ideal for applications requiring portability and intermittent use, such as inflating tires or powering pneumatic tools.

On the other hand, rotary screw pumps provide continuous air flow and are typically used in industrial settings where high volumes of air are needed. These pumps operate via two helical screws that compress the air as they rotate, resulting in a smoother and quieter operation. While they may have a higher upfront cost, their efficiency and longevity make them a worthwhile investment for businesses with heavy-duty air compressor requirements. Understanding these differences can help you choose the right pump that aligns with your specific applications, ensuring optimal performance and reliability.

Assessing Your Air Supply Needs for Specific Applications

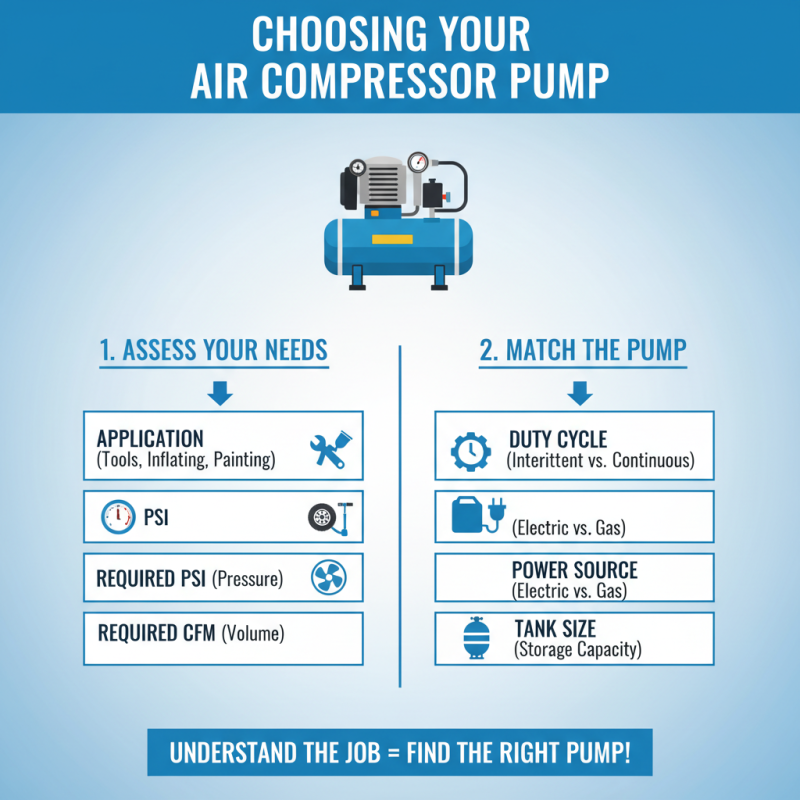

When choosing the best air compressor pump for your needs, it's essential to first assess your air supply requirements based on the specific applications you plan to use it for. Different tasks such as powering tools, inflating tires, or painting require varying levels of air pressure and volume. Understanding the responsibilities of your air compressor will help you narrow down the options available.

Tips: Consider the CFM (Cubic Feet per Minute) rating needed for your tools. For instance, pneumatic tools typically require a higher CFM, while smaller applications like tire inflation need less. Also, think about the PSI (Pounds per Square Inch) requirements; most air tools function optimally around 90-120 PSI. This will ensure that the pump you choose can provide adequate power without straining.

In addition, evaluate the duty cycle of the compressor pump. For heavy-duty applications, a continuous run time is important, whereas occasional tasks might be suited to a pump that can handle shorter bursts of use. Assessing these features against your workload will guide you in selecting a reliable air compressor pump tailored to your specific needs.

Key Features to Consider When Choosing Air Compressor Pumps

When selecting the best air compressor pumps, it’s essential to focus on key features that can significantly impact performance and efficiency. One crucial aspect is the pump design, with options ranging from single-stage to two-stage pumps. Single-stage pumps are typically suited for lower-pressure applications, while two-stage pumps are more efficient for higher pressures, which can provide a better output per horsepower. According to a report by the Compressor Manufacturers Association, two-stage pumps can deliver up to 25% more air than single-stage options at the same horsepower.

Another important feature to consider is the duty cycle of the air compressor pump. A higher duty cycle indicates that the pump can run for extended periods without overheating, which is vital for continuous use in professional settings. Data from the Air Conditioning, Heating, and Refrigeration Institute shows that pumps with a continuous duty cycle can boost overall productivity in industrial applications by nearly 30%.

**Tips:** Always evaluate the noise level of the pump, especially if it's going to be used in a workspace. Many manufacturers provide noise ratings, which can guide your choice. Also, don't overlook the compatibility with your existing equipment. Ensure the pump’s specifications match your power supply and pressure requirements to avoid compatibility issues.

Comparison of Key Features in Air Compressor Pumps

Evaluating the Power and Efficiency of Air Compressor Pumps

When selecting the best air compressor pumps, evaluating power and efficiency is crucial. The power of an air compressor pump is typically rated in horsepower (HP) or watts, determining how much air it can compress and the pressure it can achieve. Higher horsepower can lead to faster inflation and the ability to handle more demanding tasks, such as powering tools or inflating large items. However, it's essential to balance power with your specific applications to avoid unnecessary energy consumption and costs.

Efficiency also plays a significant role in the long-term performance of air compressor pumps. An efficient pump maximizes output while minimizing energy consumption. Look for features such as variable speed motors or pumps designed with high-performance elements that optimize air delivery. Moreover, the pump's duty cycle — the ratio of running time to downtime — can indicate its efficiency level; a higher duty cycle suggests a unit can operate continuously without risking overheating. By examining both power and efficiency, you can make an informed decision that meets your operational needs while ensuring cost-effectiveness.

Maintenance Tips for Prolonging the Life of Your Air Compressor Pump

When selecting the right air compressor pump for your needs, maintenance should be a top priority to ensure longevity and efficiency. According to a report by the Industrial Truck Association, regular maintenance can extend the life of an air compressor pump by up to 50%. One essential tip is to conduct routine checks on air filters and replace them as necessary. Clogged filters can restrict airflow, leading to unnecessary strain on the pump, ultimately affecting its performance and lifespan.

Additionally, monitoring the oil levels in oil-lubricated pumps is crucial. The American Society of Mechanical Engineers suggests that maintaining optimal oil levels not only lubricates the pump components but also helps in cooling and reducing wear and tear. Furthermore, regular inspection for leaks, and tightening fasteners can prevent loss of pressure and maintain efficiency. Implementing these maintenance strategies will not only enhance the performance of your air compressor pump but also save costs in the long run, as evidenced by a study from the National Institute of Standards and Technology which found that proactive maintenance can reduce operational costs by 30%.

Related Posts

-

Unmatched Quality: Elevating Global Standards with China's Premier Air Compressor Pumps

-

Exploring the Future of Air Pumps at the 138th Canton Fair 2025: Industry Trends and Insights

-

2025 Industry Trends: Innovative Solutions for the Best Air Compressor Empowering Your Business

-

Exploring Innovative Alternatives to Air Compressor Pumps for Efficient Performance

-

What is the Evolution of Air Pumps in Modern Industries and Their Impact on Efficiency

-

Unlocking the Power of Air Compressors: A Comprehensive Guide to Their Applications and Benefits