How to Choose the Right Compressor Pumps for Optimal Efficiency and Performance

Choosing the right compressor pumps is crucial for achieving optimal efficiency and performance in various applications. Whether you're in construction, manufacturing, or any industry that relies on compressed air systems, understanding the intricacies of compressor pumps can significantly impact your operational success. This guide will navigate you through the essential factors to consider when selecting compressor pumps, including pump type, power requirements, and maintenance needs. By equipping yourself with the right knowledge, you can ensure that your choice not only meets your specific requirements but also enhances overall productivity.

Join us as we explore the key elements that will help you make an informed decision and maximize the effectiveness of your compressor pump solutions.

Understanding the Different Types of Compressor Pumps Available on the Market

When selecting the right compressor pump for optimal efficiency and performance, it's essential to understand the various types available on the market. The three main modes of operation include rotary, centrifugal, and reciprocating compressors, each designed for different applications and specific requirements.

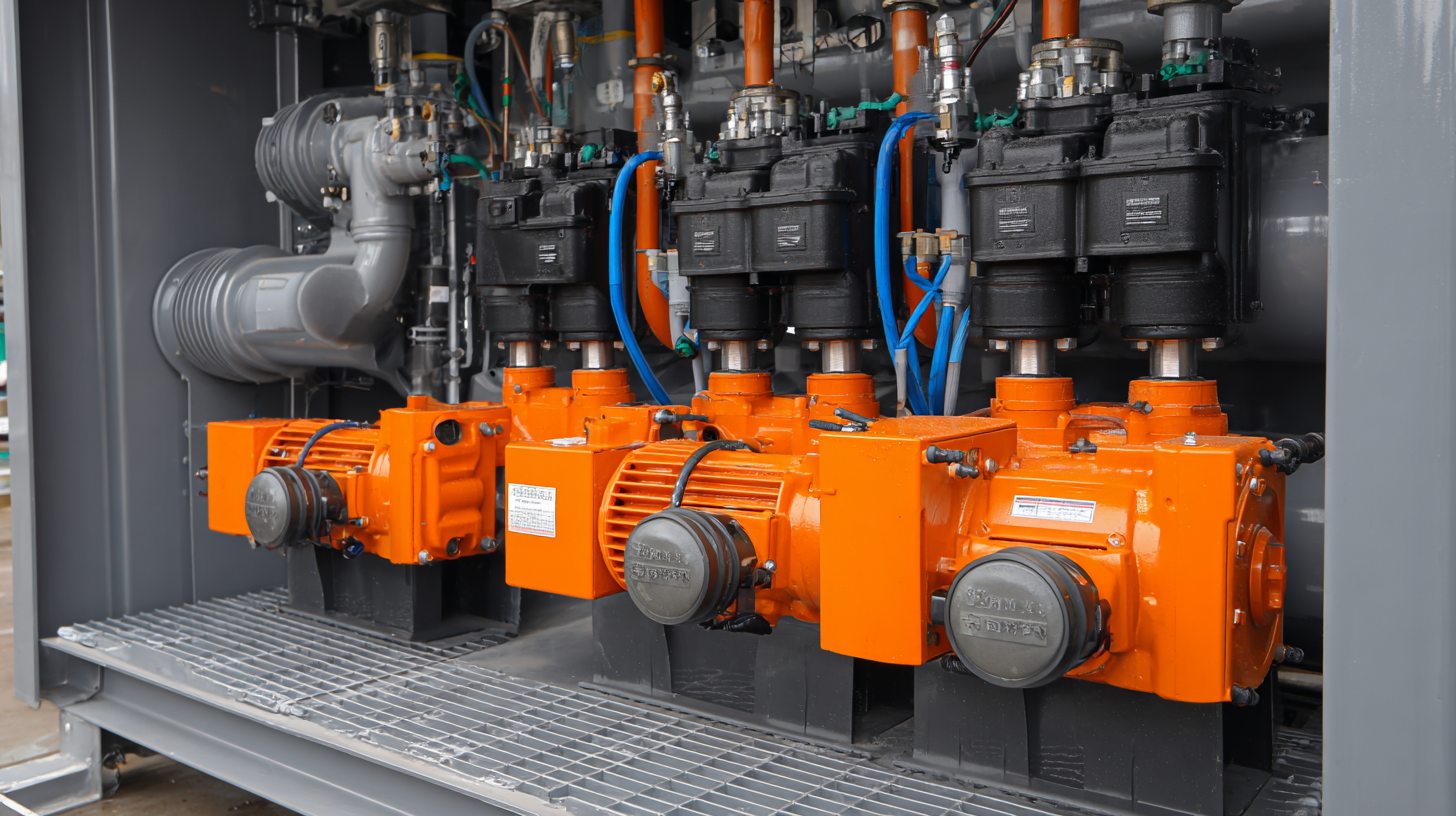

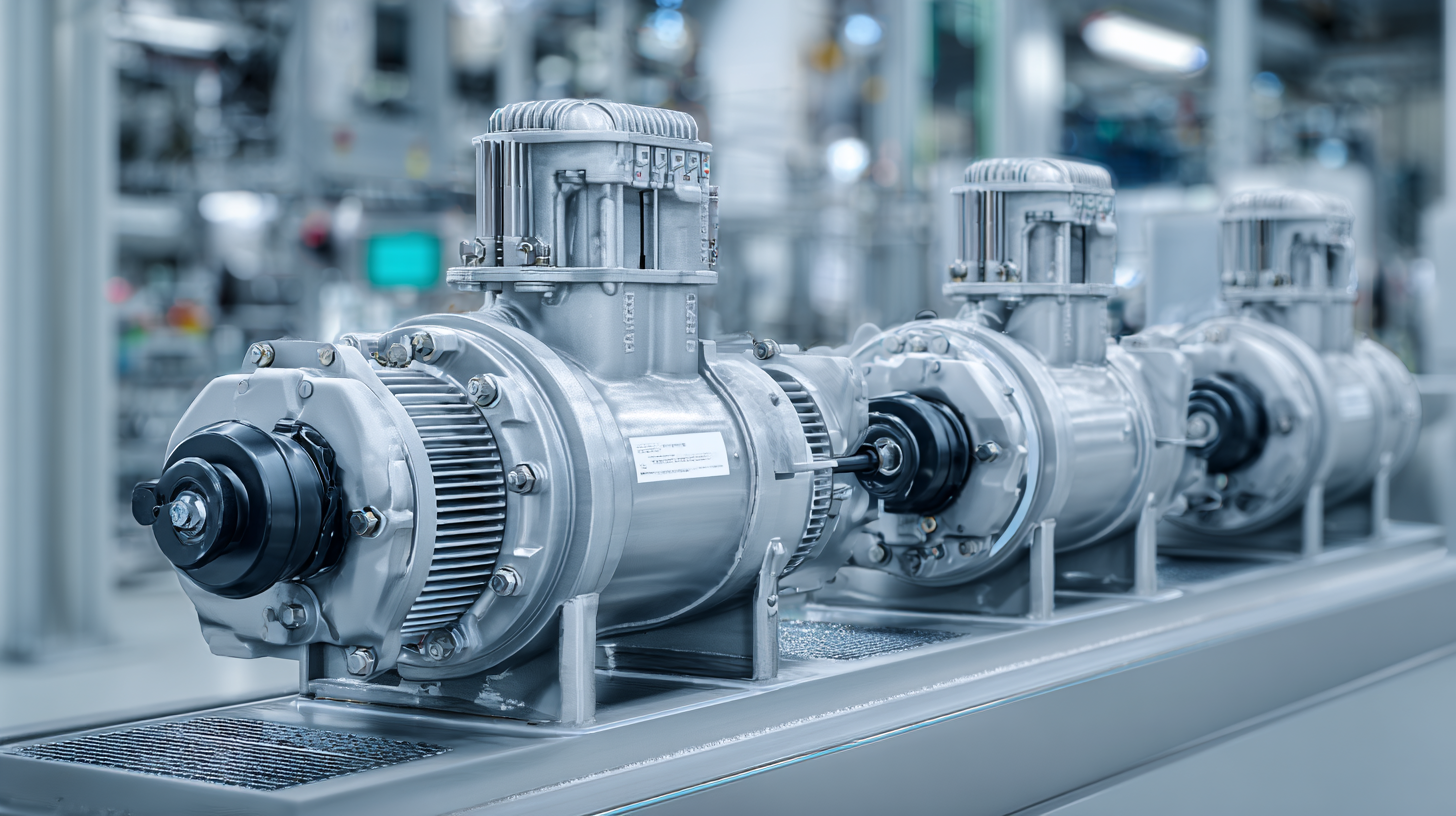

Rotary compressors are known for their continuous operation and high efficiency, making them ideal for industrial applications where consistent pressure is necessary. They also tend to have a compact design and quieter operation, appealing for environments where noise reduction is crucial.

Rotary compressors are known for their continuous operation and high efficiency, making them ideal for industrial applications where consistent pressure is necessary. They also tend to have a compact design and quieter operation, appealing for environments where noise reduction is crucial.

Centrifugal compressors, on the other hand, excel in high-flow and low-pressure applications. They leverage high-speed rotating impellers to compress gas, making them suitable for large-scale commercial uses.

Reciprocating compressors are versatile and are often used for both low- and high-pressure needs. They are commonly found in manufacturing and refrigeration systems, thanks to their adaptability and robust performance. As the global market expands, with the air compressor segment projected to grow significantly, understanding these compressor types will empower buyers to make informed decisions that align with their specific efficiency requirements and performance goals.

Evaluating Your Specific Needs: Factors to Consider Before Choosing a Compressor Pump

When selecting the right compressor pump, understanding your specific needs is vital to optimize both efficiency and performance. Key factors to consider include the application environment, energy use, and potential for integration with existing systems. For instance, industrial heat pumps are becoming increasingly significant in decarbonizing sectors and district heating systems. They can reclaim heat energy lost during chilling processes, offering potential energy savings and improved operational efficiency, which are critical in today’s eco-conscious market.

Moreover, performance evaluation is essential. Recent studies emphasize the importance of pressure drop modeling in air-source heat pumps, as it affects the overall system efficiency. Different systems demand varying pressure drop criteria, which must be factored into your selection process. An optimized choice can enhance not only the performance but also the lifespan of the equipment. Additional considerations include the sustainability of refrigerants and compliance with evolving environmental standards, emphasizing the need for manufacturers to innovate continuously. Thus, a thorough assessment of your operational requirements will guide you in choosing a compressor pump that balances efficiency, environmental impact, and cost-effectiveness.

How to Choose the Right Compressor Pumps for Optimal Efficiency and Performance

| Factor | Description | Importance | Recommended Range |

|---|---|---|---|

| Application Type | Industrial, commercial or residential use | High | Depends on usage |

| Flow Rate | The volume of air the pump can deliver | High | 10-100 CFM |

| Pressure Rating | Maximum pressure output of the pump | High | 50-175 PSI |

| Power Source | Electric, gasoline, or diesel | Medium | Depends on availability |

| Portability | Ease of transport and operation | Medium | Lightweight models preferred |

| Noise Level | The sound produced during operation | Medium | 60-80 dB |

| Maintenance Needs | Frequency and complexity of upkeep | High | Routine checks recommended |

Key Features to Look for in High-Performance Compressor Pumps

When selecting compressor pumps for optimal efficiency and performance, there are several key features to consider. First and foremost, the type of compressor pump significantly impacts its efficiency. For instance, rotary screw pumps are known for their continuous operation and lower energy consumption, making them ideal for facilities requiring constant air supply. In contrast, reciprocating pumps can deliver higher pressure but may consume more power, so understanding the specific needs of your application is crucial.

Another essential feature is the pump’s build quality and materials. High-performance compressor pumps are typically constructed from durable materials that can withstand varying temperatures and pressures. Look for pumps with corrosion-resistant coatings and components designed for longevity. Additionally, an effective cooling system within the compressor can prevent overheating and enhance the overall performance, ensuring that your pump runs smoothly under heavy loads. Regular maintenance features, such as easy access to filters and oil levels, can also simplify upkeep and extend the life of the compressor pump, resulting in better efficiency and reduced downtime.

Assessing Energy Efficiency Ratings for Compressor Pumps

When selecting compressor pumps, energy efficiency ratings are a crucial aspect to consider. These ratings provide insight into a pump's performance and operational costs. According to the 2022 report from the Department of Energy, efficient compressor pumps can operate at about 15-20% lower energy consumption compared to their less efficient counterparts. This discrepancy not only impacts operational costs but also contributes to reduced carbon footprints, making it an essential factor for environmentally conscious businesses.

Tips for selecting energy-efficient compressor pumps include seeking models with high-tier efficiency ratings such as those rated by the Energy Star program. Additionally, consider the compressor's load factor; operating a pump closer to its full capacity typically enhances efficiency. Aim for variable speed drive (VSD) compressor pumps, as studies indicate they can save up to 50% in energy costs compared to traditional constant speed models.

Furthermore, analyze lifecycle costs rather than just initial purchase price. A report by the International Energy Agency highlights that while the upfront investment for energy-efficient models may be higher, over time, the savings in energy bills and maintenance often offset the initial costs significantly. Always ensure to review the manufacturer’s energy efficiency reports and choose pumps that suit your operational requirements precisely.

Maintenance Tips to Enhance the Longevity and Efficiency of Your Compressor Pump

When it comes to maintaining the efficiency and longevity of your compressor pump, regular maintenance is key. Ensuring that your compressor operates smoothly requires periodic checks and servicing. One essential tip is to consistently change the oil and replace air filters according to the manufacturer’s recommendations. This simple step can significantly reduce wear on components and enhance overall performance.

Another important practice involves monitoring the environment in which your compressor operates. Excessive dust and debris can lead to blockages and overheating. Keeping the area clean and ensuring proper ventilation can help prevent potential issues. Additionally, regularly inspect hoses and fittings for any signs of wear or leaks, which can compromise efficiency.

Lastly, it's beneficial to incorporate condition monitoring systems into your maintenance routine. By utilizing smart technologies, you can easily track performance and address any inefficiencies before they escalate into major problems. This proactive approach not only enhances the longevity of your compressor pump but also ensures that it continues to deliver optimal performance for your specific needs.

Related Posts

-

The Ultimate Guide to Selecting the Best Compressor Pumps: Industry Insights and Expert Tips

-

Superior Compressor Parts from China's Leading Factories Trust Built on Quality

-

Choosing Top Quality Manufacturers for Best Industrial Compressors

-

Solutions for Optimizing Your Industrial Efficiency with Best Air Compressor Accessories

-

Ultimate Guide to Choosing the Best Air Compressor Accessories for Your Needs

-

Unlocking Efficiency with Best Rotary Screw Air Compressors Technical Specs and Buying Guide