Understanding the Efficiency and Applications of Rotary Air Compressors in Modern Industries

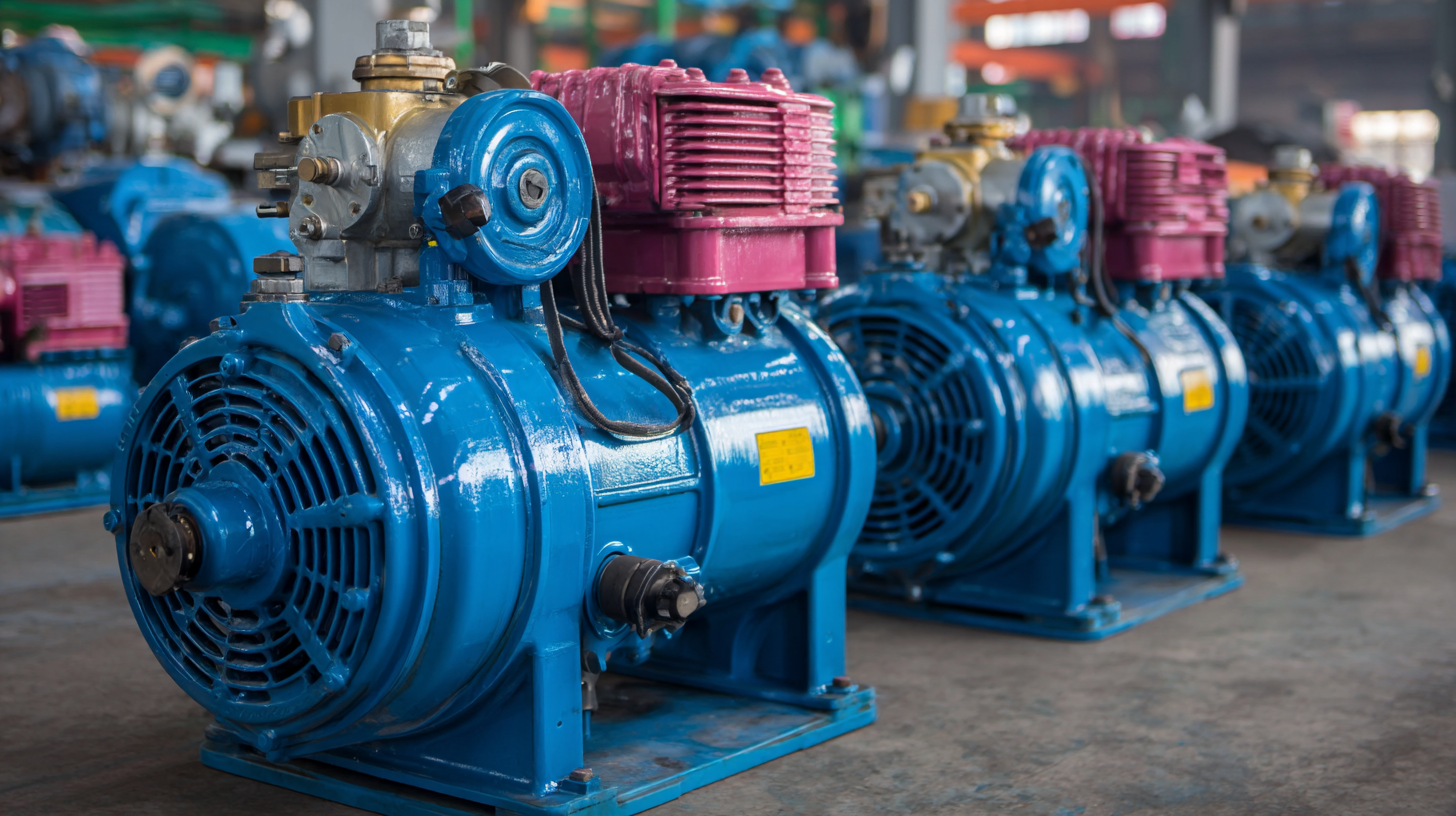

The rotary air compressor has emerged as a pivotal technology in modern industries, characterized by its efficiency and versatility. This type of air compressor operates on a unique mechanism that compresses air through rotary motion, enabling a continuous flow of compressed air. As industries increasingly seek to enhance productivity and reduce operational costs, the advantages of rotary air compressors become increasingly apparent. Their compact design, reliability, and quiet operation make them invaluable in various applications, from manufacturing and construction to food processing and automotive industries. Furthermore, the energy efficiency of rotary air compressors not only contributes to lower energy bills but also supports sustainability initiatives by reducing carbon footprints. This introduction provides an overview of the functionality and benefits of rotary air compressors, setting the stage for a deeper exploration of their efficiency and wide-ranging applications in contemporary industrial settings.

Exploring Rotary Air Compressors: A Key to Enhanced Industrial Efficiency

Rotary air compressors have emerged as fundamental tools in modern industries, significantly contributing to operational efficiency and productivity. By utilizing a continuous process that compresses air in a smooth, uninterrupted flow, these compressors minimize energy loss and ensure a reliable supply of compressed air. This technology not only enhances performance but also reduces the wear and tear on equipment, making it a preferred choice in various applications ranging from manufacturing to pharmaceuticals.

Rotary air compressors have emerged as fundamental tools in modern industries, significantly contributing to operational efficiency and productivity. By utilizing a continuous process that compresses air in a smooth, uninterrupted flow, these compressors minimize energy loss and ensure a reliable supply of compressed air. This technology not only enhances performance but also reduces the wear and tear on equipment, making it a preferred choice in various applications ranging from manufacturing to pharmaceuticals.

Tips for Optimal Use of Rotary Air Compressors:

- Regular maintenance is essential to keep the compressor running efficiently. Check filters and oil levels frequently to prevent performance dips.

- Consider the size of the compressor relative to your application to avoid overworking the unit, which can lead to increased energy consumption and premature failure.

- Utilize the right accessories, such as air dryers and filtration systems, to improve the quality of the compressed air and protect sensitive machinery.

Investing in rotary air compressors can yield substantial returns by enhancing both the quality and efficiency of industrial processes. Their ability to provide a steady supply of air, coupled with energy efficiency, positions them as invaluable assets across various sectors.

Key Performance Metrics: Analyzing CFM, PSI, and Power Usage in Rotary Compressors

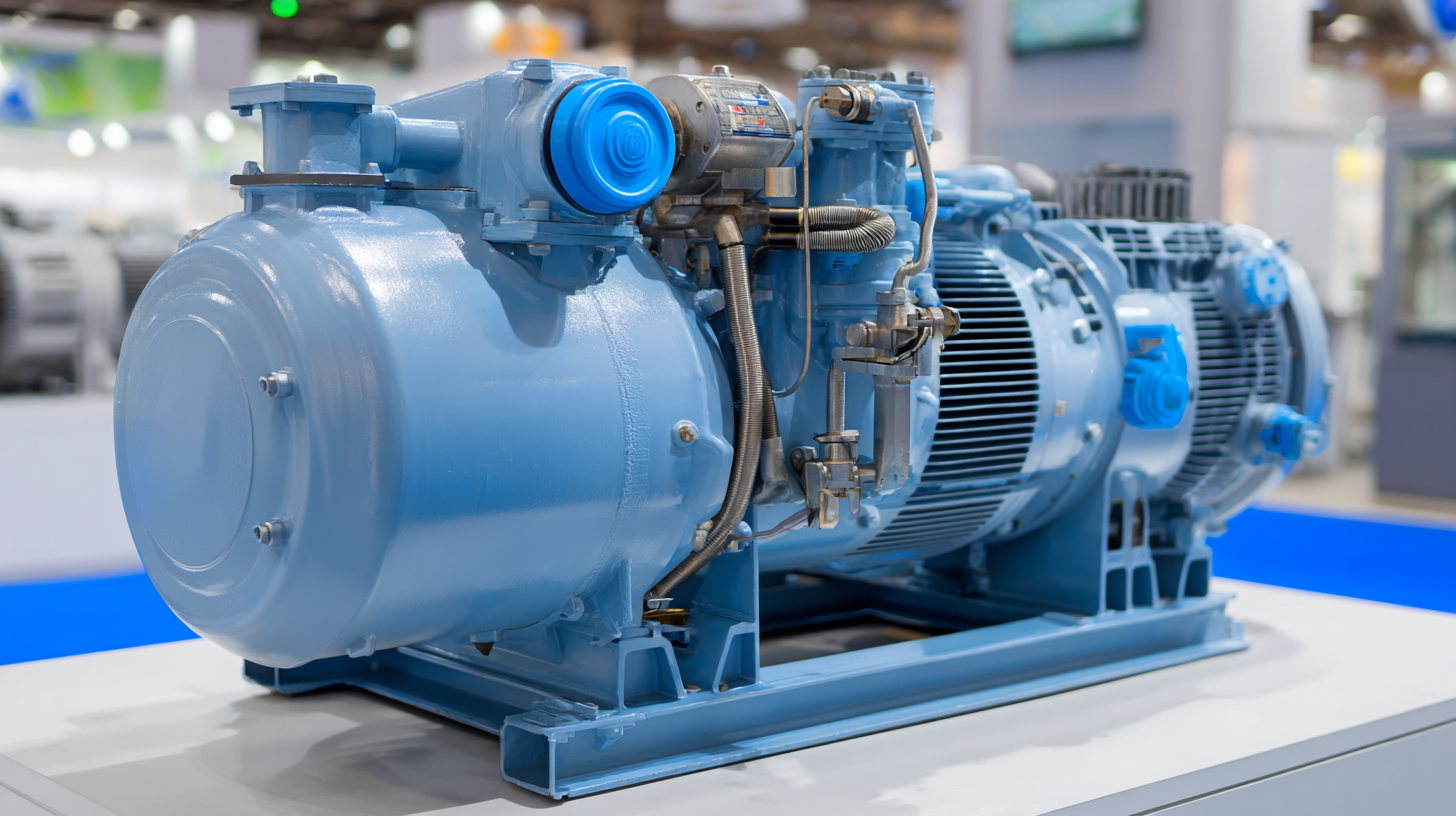

Rotary air compressors have become indispensable in modern industries due to their efficiency and versatility in various applications. Understanding key performance metrics such as CFM (Cubic Feet per Minute), PSI (Pounds per Square Inch), and power usage is critical for optimizing their performance. For instance, a recent analysis indicates that rotary compressors typically deliver higher CFM ratings compared to their reciprocating counterparts, making them ideal for continuous operation in tasks requiring a steady airflow.

Rotary air compressors have become indispensable in modern industries due to their efficiency and versatility in various applications. Understanding key performance metrics such as CFM (Cubic Feet per Minute), PSI (Pounds per Square Inch), and power usage is critical for optimizing their performance. For instance, a recent analysis indicates that rotary compressors typically deliver higher CFM ratings compared to their reciprocating counterparts, making them ideal for continuous operation in tasks requiring a steady airflow.

Moreover, the air compressor market is projected to experience substantial growth, with estimates predicting a significant size increase by 2032, driven by the demand for reliable and efficient power solutions across multiple sectors. Power usage is another vital metric, as rotary air compressors are designed to be energy-efficient, which can lead to substantial cost savings for businesses. Current statistics reveal that efficient power management in these systems can reduce operational costs by up to 30%, underscoring their role in energy-conscious industrial practices. The integration of rotary compressors into various applications, from construction to manufacturing, highlights their significance in bolstering productivity and performance in today's competitive landscape.

Applications of Rotary Air Compressors in Manufacturing: Data-Driven Insights

Rotary air compressors have become indispensable in modern manufacturing due to their efficiency and versatility. These compressors utilize a rotary mechanism to compress air, making them ideal for continuous operations. The data-driven insights from recent studies highlight how industries leverage rotary air compressors to enhance productivity and reduce energy consumption. With their ability to deliver a steady airflow, these compressors support various applications, from powering pneumatic tools to facilitating processes such as painting and packaging.

In manufacturing settings, the adaptation of rotary air compressors has led to significant improvements in operational efficiency. For example, industries that require high-volume compressed air, such as automotive and food processing, benefit from the reduced maintenance requirements and longer operational lifespans of rotary systems. Furthermore, advancements in technology have enabled predictive maintenance, ensuring that potential issues are addressed before they lead to costly downtimes. By integrating data analytics, manufacturers can monitor compressor performance in real-time, optimize energy usage, and make informed decisions that contribute to overall productivity gains.

Cost-Benefit Analysis: Evaluating Energy Savings from Rotary Air Compressors

The air compressor market is witnessing significant growth, driven largely by the increasing adoption of rotary air compressors across various industries. These compressors are recognized for their efficiency and energy-saving capabilities, making them a cost-effective choice for manufacturers looking to optimize their operations. By transitioning to rotary air compressors, industries can achieve substantial energy savings, which directly impacts operational costs and enhances overall productivity.

In the broader context, the global air compressor market is projected to reach USD 40.16 billion by 2031 from USD 27.92 billion in 2024, growing at a compound annual growth rate (CAGR) of 5.33%. Specific regions such as Ohio and Michigan are also experiencing market growth, with the air compressor market in these states estimated at USD 324.8 million in 2024 and a projected CAGR of 3.4% through 2030. The industrial air compressors sector, valued at USD 38 billion, is expected to expand further, aligning with trends in technological advancements and sustainability initiatives that promote the use of energy-efficient equipment.

Future Trends in Rotary Compression Technology and Industry Adoption Rates

As the demand for efficiency in industrial processes continues to rise, rotary air compressors are witnessing a notable increase in adoption across various sectors. The global market for rotary air compressors is projected to expand significantly, driven by their ability to deliver high performance with lower operational costs. Innovations in rotary compression technology are shaping future trends, including advancements in energy efficiency and the development of smarter, more integrated systems. These innovations are expected to cater not only to traditional manufacturing and oil and gas applications but also to emerging industries such as renewable energy and electric vehicle production.

Moreover, the market dynamics indicate a shift in industry preferences from conventional to more advanced compression solutions. The projected compound annual growth rate suggests that rotary air compressors will play a crucial role in enhancing productivity and sustainability in modern industries. As organizations increasingly focus on reducing carbon footprints and operational expenses, the adoption of rotary compressors, particularly in oil-free lubrication applications, is set to gain momentum. As these compressors become integral to various industrial processes, their versatility will further cement their status as essential tools for the future of industrial automation and efficiency.

Related Posts

-

7 Essential Tips for Sourcing High-Efficiency Air Compressors: Maximize Your ROI!

-

Unlocking the Power of Air Compressors: A Comprehensive Guide to Their Applications and Benefits

-

7 Essential Tips to Maximize the Efficiency of Air Compressors in Your Operations

-

15 Best Air Compressor Accessories to Enhance Your Efficiency

-

7 Best Air Dryers That Transform Your Drying Experience

-

Global Excellence in Manufacturing: The Pride of China’s Best Screw Air Compressors