7 Essential Tips for Sourcing High-Efficiency Air Compressors: Maximize Your ROI!

In today's rapidly evolving industrial landscape, sourcing high-efficiency air compressors has become paramount for businesses aiming to maximize their return on investment (ROI). According to a report by the International Energy Agency, air compressors account for nearly 10% of global industrial electricity consumption, highlighting the critical need for efficiency in this essential equipment. Additionally, the market for air compressors is projected to reach USD 38.3 billion by 2027, growing at a compound annual growth rate of 5.7%. By focusing on the right sourcing strategies, companies can not only reduce operational costs but also improve productivity and sustainability. In this blog, we will provide you with seven essential tips to guide your selection process and ensure that you choose the best high-efficiency air compressors for your business needs.

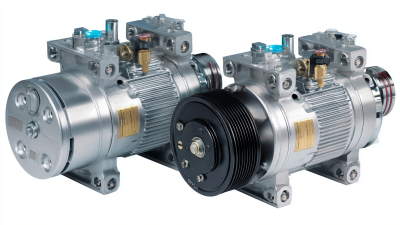

Key Considerations for Selecting Air Compressors Based on Industry Efficiency Ratings

When selecting high-efficiency air compressors, it is essential to focus on industry efficiency ratings, which can directly impact your return on investment (ROI). As energy efficiency is recognized as the “first fuel” in clean energy transitions, understanding the efficiency ratings can help identify compressors that provide the best performance while minimizing energy consumption. Factors such as the compressor's energy usage, maintenance costs, and overall reliability must be considered to ensure optimal performance and cost savings in the long run.

Additionally, adopting a systematic approach to evaluate compressors based on multiple criteria decision-making techniques is beneficial. This method allows you to weigh different aspects, such as sustainability, scalability, and the specific needs of your operation. Just as buildings are evaluated for passive energy consumption optimization, so too can air compressor systems be assessed for their effectiveness in reducing carbon footprints while maximizing operational efficiency. By focusing on these key considerations, organizations can select air compressors that not only meet their needs but also contribute to broader environmental goals.

Understanding the Impact of Operating Costs on Long-Term ROI of Air Compressors

Understanding the impact of operating costs on the long-term ROI of air compressors is crucial for achieving efficiency gains. Compressed air systems are often oversized, leading to unnecessary energy waste and inflated costs. By right-sizing your system to match peak demand, you can optimize performance and significantly decrease operating expenses. Furthermore, implementing leak detection and repair programs can reduce compressed air waste by up to 50%. This not only conserves energy but also translates to considerable savings on your utility bills, thereby enhancing your overall return on investment.

As trends indicate a steady growth in the portable air compressor market, businesses must prioritize strategies that maximize efficiency while minimizing costs. The rise of compressor rental services reflects a demand for flexible, low-capital expenditure solutions, allowing companies to better manage resources and avoid the pitfalls of owning oversized systems. Investing in high-efficiency air compressors with a focus on operational sustainability will not only provide immediate financial benefits but will also position businesses for long-term success in an increasingly competitive landscape.

Evaluating the Latest Technologies in Air Compressors for Enhanced Energy Efficiency

When it comes to selecting high-efficiency air compressors, evaluating the latest technologies is crucial for optimizing energy performance. According to a report by the U.S. Department of Energy, air compressors can account for up to 30% of a facility's energy usage. This percentage underscores the importance of investing in equipment that not only performs well but also adheres to energy efficiency standards. Technologies such as variable speed drives (VSD) and advanced monitoring systems can significantly reduce energy consumption by adjusting the compressor's output to match the air demand.

Additionally, studies show that modern air compressors featuring integrated smart controls can lead to energy savings of up to 50% compared to older models. These systems monitor real-time data and predict demand patterns, allowing for more efficient operation. Investing in air compressors that incorporate these cutting-edge technologies not only enhances performance but also maximizes return on investment (ROI) by lowering operational costs. The commitment to energy efficiency not only benefits the bottom line but also contributes to more sustainable industrial practices.

Energy Efficiency Ratings of Air Compressors

Strategies for Sourcing Reliable Suppliers of High-Performance Air Compressors

When sourcing high-performance air compressors, selecting reliable suppliers is crucial for maximizing ROI. Start by conducting thorough market research to identify potential suppliers with a proven track record. Keep an eye on the latest industry reports, like those covering the air compressor rental market, which indicate that the sector is poised for significant growth, with an anticipated value of USD 8,221.1 million by 2033. This data underscores the importance of partnering with suppliers who not only offer quality products but also understand market trends and demands.

Engaging with suppliers who provide comprehensive solutions—such as compressors paired with dryers and filters—can enhance operational efficiency. This integrated approach aligns well with the ongoing industry shifts towards energy efficiency and resource optimization. By choosing suppliers that emphasize technology advancements and sustainable practices, businesses can ensure their air compression systems operate at peak efficiency while reducing energy costs. Adopting these strategies will not only streamline sourcing processes but also position your operations for long-term success and sustainability.

The Role of Maintenance and Upkeep in Maximizing Air Compressor Efficiency and Lifespan

When it comes to maximizing the efficiency and lifespan of air compressors, maintenance and upkeep are paramount. Regular servicing can prevent costly breakdowns and ensure that your equipment operates at peak performance. One essential tip is to maintain a consistent scheduling of inspections and preventive maintenance tasks. This can include checking for air leaks, ensuring proper lubrication, and replacing worn parts before they lead to more significant issues.

Another important aspect is to regularly monitor system performance. Keeping an eye on pressure readings and energy consumption can help identify inefficiencies. For instance, if you notice a drop in pressure or an increase in energy usage, it might be time for an inspection. Additionally, investing in high-quality air filters is crucial; clean filters can drastically improve airflow and compressor efficiency, leading to better overall performance.

Finally, training your staff on the proper operation and maintenance of air compressors can significantly contribute to their longevity. Educating employees about the importance of routine checks and encouraging proactive reporting of any unusual sounds or performance issues can help catch problems before they escalate. Prioritizing these maintenance practices will not only enhance efficiency but will also improve your return on investment significantly.

Related Posts

-

Choosing Top Quality Manufacturers for Best Industrial Compressors

-

Unlocking Efficiency: The Advantages of Choosing Industrial Compressors for Your Business

-

Global Export Powerhouse Producing the Finest Rotary Screw Air Compressors from China

-

Ultimate Guide to Choosing the Best Piston Compressor for Your Needs

-

2025 Industry Trends: Innovative Solutions for the Best Air Compressor Empowering Your Business

-

Unlocking Efficiency with Best Rotary Screw Air Compressors Technical Specs and Buying Guide