What is the Evolution of Air Pumps in Modern Industries and Their Impact on Efficiency

In the dynamic landscape of modern industries, the evolution of air pumps has played a crucial role in enhancing operational efficiency and productivity. These mechanical devices, traditionally viewed as mere tools for transferring air, have transformed into sophisticated systems that integrate advanced technologies and automation. As industries strive for greater sustainability and performance, understanding the development of air pumps becomes essential. From their humble beginnings to the latest innovations, these pumps not only facilitate various processes but also significantly reduce energy consumption, optimize workflows, and minimize environmental impact.

This blog will explore the journey of air pumps and their growing importance in different sectors, shedding light on how they have revolutionized the way we approach efficiency in manufacturing, automotive, and beyond.

How Air Pumps Have Transformed Industrial Processes Over the Decades

The evolution of air pumps has significantly transformed industrial processes, enhancing both productivity and efficiency across various sectors. Historically, air pumps were rudimentary, often limited to manual operation and basic functions. Over the decades, advancements in technology have introduced automated systems and smart controls, allowing for precise regulation of air pressure and flow rates. According to a recent market analysis by Industry Insights, the global air pump market is expected to reach $XX billion by 2025, driven primarily by innovations in manufacturing and environmental sustainability.

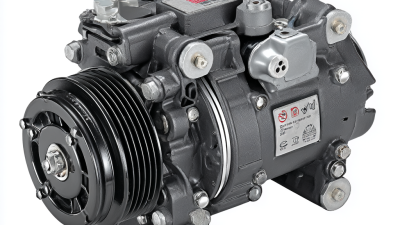

As industries have become increasingly reliant on automation, the role of air pumps has expanded beyond mere inflation tasks to critical components in pneumatic systems, material handling, and even cooling processes. For example, the automotive and food processing sectors have reported productivity increases of up to 30% after upgrading to modern air pump technologies. Utilizing variable speed drives and energy-efficient designs, companies can significantly reduce power consumption, aligning with the global push towards sustainable industrial practices.

Tips: When considering an upgrade to air pump systems, assess your current energy consumption and potential savings. Investing in high-efficiency air pumps not only enhances performance but can lead to substantial cost reductions over time. Additionally, regular maintenance of your air pump systems ensures optimal operation and longevity, further boosting efficiency in your industrial processes.

Key Technological Advancements in Air Pump Design for Modern Efficiency

The evolution of air pumps in modern industries has seen significant technological advancements that have greatly improved efficiency. Contemporary air pumps are designed with precision engineering, incorporating materials that are lighter yet more durable. Innovations in motor technology, such as the integration of brushless motors, provide greater energy efficiency and reduced maintenance costs. These advancements not only enhance the performance of air pumps but also contribute to the sustainability goals of industries by minimizing energy consumption.

Tip: When selecting an air pump for your application, consider the efficiency ratings provided by the manufacturer to ensure you are investing in technology that aligns with your operational goals.

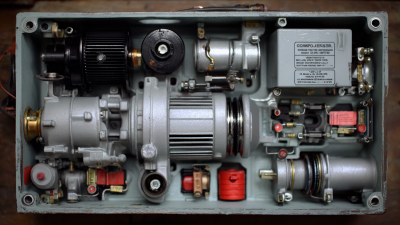

Another noteworthy improvement is the development of smart air pumps that utilize IoT (Internet of Things) technology. These pumps can communicate with other systems, allowing for real-time monitoring and adjustments based on specific requirements. This automation leads to optimized performance and less downtime, which is crucial for maintaining productivity in fast-paced industrial environments.

Tip: Implementing smart air pump systems in your operations can enhance productivity by providing data analytics that help in predicting maintenance needs, thus avoiding unexpected failures.

Evolution of Air Pumps Efficiency in Modern Industries

The Role of Air Pumps in Sustainable Manufacturing Practices

Air pumps have become integral to sustainable manufacturing practices, driving efficiency while minimizing environmental impact. These devices, which play a crucial role in operating various systems such as pneumatic equipment, can enhance energy usage in factories. By using air pumps that are specifically designed for lower power consumption, manufacturers can significantly reduce their carbon footprint, making operations more eco-friendly.

When considering the implementation of air pumps, it's essential to focus on selecting high-efficiency models. Tips for achieving the best results include regularly maintaining and servicing air pumps to ensure optimal performance and longevity. Additionally, manufacturers should assess their air demand and choose pumps that match their needs without excess capacity, as this can lead to energy wastage.

Another important aspect is integrating renewable energy sources to power air pumps. Utilizing solar panels or wind energy can further enhance sustainability, allowing manufacturers to operate in a greener way. By investing in advanced technologies and adopting these tips, industries can not only improve their efficiency but also contribute to a more sustainable future.

What is the Evolution of Air Pumps in Modern Industries and Their Impact on Efficiency

| Year | Type of Air Pump | Efficiency Improvement (%) | Applications | Environmental Impact |

|---|---|---|---|---|

| 2000 | Diaphragm Pump | 15 | Chemical Processing | Reduced emissions |

| 2005 | Rotary Screw Pump | 20 | HVAC Systems | Low energy consumption |

| 2010 | Vane Pump | 25 | Food and Beverage | Better hygiene |

| 2015 | Peristaltic Pump | 18 | Pharmaceuticals | Minimal waste |

| 2020 | Turbo Pump | 30 | Industrial Applications | Reduced carbon footprint |

Evaluating the Impact of Air Pumps on Energy Consumption in Industries

Air pumps have significantly transformed modern industries, not only enhancing operational efficiency but also playing a crucial role in energy consumption management. As industries strive for sustainability, the focus has shifted towards optimizing air pump performance to minimize energy use. Advanced technologies such as variable speed drives and smart control systems allow for better adaptability to fluctuating production needs, effectively reducing operational costs while maintaining high efficiency.

The impact of air pumps on energy consumption is evident in various sectors including manufacturing, HVAC, and food processing. Traditional pumps often operated at fixed speeds, leading to excessive energy use during low-demand periods. However, modern pumps now incorporate intelligent algorithms that adjust their performance in real time, ensuring that energy consumption aligns closely with actual operational requirements. This evolution not only contributes to lower energy bills but also supports industries in meeting environmental standards and reducing their carbon footprint. As businesses continue to invest in energy-efficient air pump technologies, the benefits extend beyond economic savings to fostering a more sustainable industrial landscape.

Future Trends in Air Pump Technology and Their Potential Benefits

The evolution of air pump technology has paved the way for significant advancements in efficiency, especially in modern industries where energy consumption and sustainability are paramount. As industries increasingly adopt heat pumps, they stand to benefit from their dual functionality of providing heating in winter and cooling in summer. This not only leads to improved comfort but also significantly lowers the carbon footprint of commercial buildings, aligning with global sustainability goals. With a potential to halve energy consumption in such environments, heat pumps are readily becoming integral components in the fight against climate change.

Looking ahead, future trends in air pump technology are poised to enhance energy efficiency even further. Innovations in hybrid systems that combine solar and wind energy with air pump technology could address existing challenges while maximizing efficiency and sustainability. Furthermore, cost-effectiveness remains a crucial focus, with studies indicating that many U.S. households could utilize air-source heat pumps effectively. As the industry responds to these demands, the push for reduced installation costs and increased accessibility will determine how widely these innovative solutions can be implemented. The transition to advanced air pump systems represents a compelling opportunity for both energy efficiency and environmental stewardship.

Related Posts

-

Unmatched Quality: Elevating Global Standards with China's Premier Air Compressor Pumps

-

2025 Industry Trends: Innovative Solutions for the Best Air Compressor Empowering Your Business

-

5 Best Screw Compressor Parts You Should Invest In

-

Ultimate Guide to Choosing the Best Air Compressor Accessories for Your Needs

-

Global Excellence in Manufacturing: The Pride of China’s Best Screw Air Compressors

-

7 Essential Tips for Finding the Best Compressor Parts for Your Needs