Exploring Innovative Alternatives to Air Compressor Pumps for Efficient Performance

In recent years, the demand for air compressor pumps has surged, driven by advancements in various industrial applications and the growing emphasis on energy efficiency. According to a report by MarketsandMarkets, the air compressor market is projected to reach $40.6 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5.1% from 2021 to 2026. This growth presents an opportunity for industries to explore innovative alternatives to traditional air compressor pumps that not only enhance performance but also reduce energy consumption and operational costs.

As organizations seek to improve sustainability and reduce their carbon footprints, alternative technologies such as regenerative blowers and vacuum pumps are becoming increasingly viable options. This blog delves into these innovative alternatives, examining their efficiency, cost-effectiveness, and potential to revolutionize the air compression landscape, positioning them as key players in shaping the future of pneumatic systems.

Innovative Technologies Revolutionizing Air Compression Systems

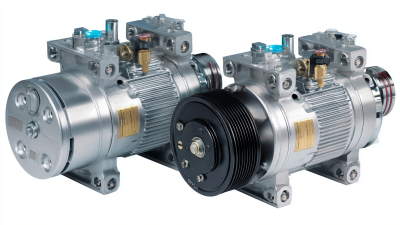

The landscape of air compression technology is evolving rapidly, driven by the quest for efficiency and sustainability. Innovative technologies are now providing alternatives to traditional air compressor pumps, reshaping how industries perceive air compression systems. For instance, advancements in variable speed drive (VSD) technology allow compressors to adjust their speed based on air demand, resulting in significant energy savings and more precise control over output. This flexibility not only enhances performance but also extends the lifespan of equipment by reducing wear and tear.

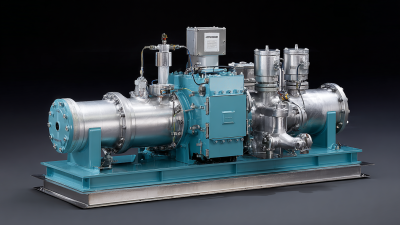

Another noteworthy innovation is the incorporation of rotary screw technology, which has been enhanced to deliver lower noise levels and increased energy efficiency. These compressors utilize a seamless design to minimize energy loss during operation. Furthermore, advancements in smart technology and IoT integration enable real-time monitoring and diagnostics, allowing operators to optimize performance and proactively address any issues. As these innovative technologies continue to gain traction, they promise to revolutionize the efficiency of air compression systems, paving the way for a more sustainable industrial future.

Benefits of Alternative Solutions Over Traditional Air Pumps

When considering alternatives to traditional air compressor pumps, one can uncover a variety of innovative solutions that offer enhanced efficiency and performance. Electric pumps, for instance, provide a quieter operation and reduced maintenance needs compared to their air compressor counterparts. Additionally, these electric models can achieve a similar pressure output with lower energy consumption, making them a sustainable choice for businesses looking to minimize their environmental footprint.

When considering alternatives to traditional air compressor pumps, one can uncover a variety of innovative solutions that offer enhanced efficiency and performance. Electric pumps, for instance, provide a quieter operation and reduced maintenance needs compared to their air compressor counterparts. Additionally, these electric models can achieve a similar pressure output with lower energy consumption, making them a sustainable choice for businesses looking to minimize their environmental footprint.

Another promising alternative is the use of regenerative blowers. These devices convert mechanical energy directly into airflow without the need for complex rotary mechanisms. This not only results in fewer moving parts, reducing maintenance and downtime, but also leads to a more continuous air pressure supply. Moreover, regenerative blowers are capable of operating in a wide range of settings, offering versatility that traditional air pumps often lack. By investing in these innovative alternatives, companies can achieve better operational efficiency while also benefiting from cost savings over time.

Comparative Analysis of Different Air Compression Methods

In recent years, the air compression industry has witnessed a surge in innovative technologies seeking to enhance efficiency and reduce energy consumption. Traditional air compressor pumps, while widely used, often fall short in delivering optimal performance. Various alternatives have emerged, showcasing significant advancements in compression methods. For instance, rotary-vane and scroll compressors are gaining traction due to their quieter operation and higher reliability. According to a report by Research and Markets, the global market for alternative air compression technologies is expected to reach $12 billion by 2026, growing at a compound annual growth rate (CAGR) of 5.6%.

Moreover, alternative methods such as osmosis-based compressors and pneumatic systems are being investigated for their potential in energy efficiency. A study published in the Journal of Cleaner Production highlights that these methods can reduce energy consumption by up to 40% compared to conventional piston compressors. By leveraging alternative air compression technologies, industries not only stand to benefit from enhanced performance but also contribute to sustainability efforts by minimizing their carbon footprint. The shift towards these innovative solutions marks a significant evolution in the pursuit of efficient air compression systems.

Real-World Applications of Innovative Compressor Alternatives

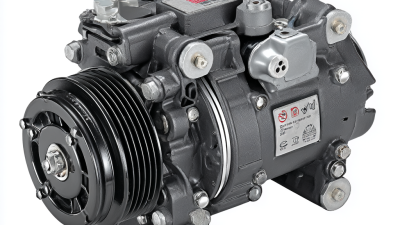

In recent years, industries have been exploring innovative alternatives to traditional air compressor pumps to enhance efficiency and reduce operational costs. These alternatives include devices like scroll pumps, diaphragm pumps, and even advanced technologies like kinetic energy recovery systems. Each of these options presents unique benefits that can greatly improve performance in real-world applications such as manufacturing, automotive, and even in the medical field.

For instance, scroll pumps are particularly noted for their quiet operation and relatively low maintenance requirements. They are well-suited for applications where noise reduction is crucial, such as in laboratories and medical facilities. On the other hand, diaphragm pumps are ideal for handling corrosive or viscous fluids, making them a popular choice in chemical processing and food industries.

Tips for industries looking to switch to these innovative alternatives include conducting a thorough analysis of their specific needs and usage patterns. It's essential to evaluate the total cost of ownership, including maintenance and energy efficiency, to ensure a sound investment. Additionally, consulting with manufacturers or experts in the field can provide valuable insights into the most suitable technology for your unique application.

Future Trends in Air Compression Technology and Efficiency Solutions

As industries strive for greater efficiency and sustainability, the evolution of air compression technology is set to transform operational practices. The global air compressor market is expected to reach USD 40 billion by 2027, growing at a CAGR of 4.5% from 2020, according to a recent report by Markets and Markets. This surge is driven by increasing demand for energy-efficient solutions and innovative technologies that minimize energy consumption while maximizing output.

Emerging alternatives to traditional air compressor pumps include variable speed drive (VSD) systems and hybrid technologies that combine pneumatic and electric systems. A study by the Department of Energy reveals that employing VSD can reduce energy costs by up to 50% in some applications. Furthermore, advancements in smart technologies enable predictive maintenance, optimizing compressor performance and enhancing overall system efficiency. As industries adopt these innovations, proactive investments in air compression technology will not only contribute to operational efficiency but also align with corporate sustainability goals, marking a significant shift in future manufacturing landscapes.

Innovative Alternatives to Air Compressor Pumps

This chart illustrates the efficiency performance of various innovative alternatives to traditional air compressor pumps. The data represents the energy efficiency rating and maximum output pressure of each solution, highlighting future trends in air compression technology.

Related Posts

-

Unmatched Quality: Elevating Global Standards with China's Premier Air Compressor Pumps

-

2025 Industry Trends: Innovative Solutions for the Best Air Compressor Empowering Your Business

-

Finding Quality Suppliers for Best Air Dryers with Industry Insights and Data

-

Future Trends in the Piston Compressor Market Leading to 2025 Insights and Predictions

-

Ultimate Guide to Choosing the Best Piston Compressor for Your Needs

-

7 Expert Tips for Choosing the Best Industrial Air Compressors Based on 2023 Market Trends