Global Excellence in Pneumatic Parts: Engineered in China for Unmatched Performance

In the realm of industrial applications, pneumatic parts have emerged as a cornerstone of efficiency and reliability, driving automation across various sectors. The global market for pneumatic components is projected to reach $50 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.5% from 2020 to 2025, according to industry reports. These components are vital for applications ranging from robotics to manufacturing machinery, offering unmatched performance due to their lightweight construction and adaptability.

Engineered in China, pneumatic parts not only meet rigorous international standards but also cater to diverse industrial needs by providing tailored solutions for unique operational challenges. As industries diversify and innovate, understanding the characteristics and applicability of various types of pneumatic parts becomes crucial for ensuring optimal performance and productivity.

The Evolution of Pneumatic Parts Manufacturing in China

The evolution of pneumatic parts manufacturing in China has been remarkable, positioning the country as a global leader in the sector. According to a recent report by Markets and Markets, the global pneumatic market size is projected to reach USD 41.06 billion by 2026, with China accounting for a significant share due to its rapid industrialization and technological advancements. The country has embraced automation and smart manufacturing, which has led to improved efficiency and quality in the production of pneumatic components.

In addition, China has made substantial strides in research and development, with a focus on producing high-performance pneumatic parts that meet international standards. Reports from the China National Machinery Industry Federation indicate that the sector is increasingly adopting advanced materials and innovative designs, enhancing product durability and functionality. This commitment to excellence not only satisfies local demand but also positions Chinese manufacturers as key players in the global market, supplying top-tier pneumatic products to industries such as automotive, aerospace, and automation. As this trend continues, the future of pneumatic manufacturing in China looks exceedingly promising.

Key Features of High-Performance Pneumatic Components

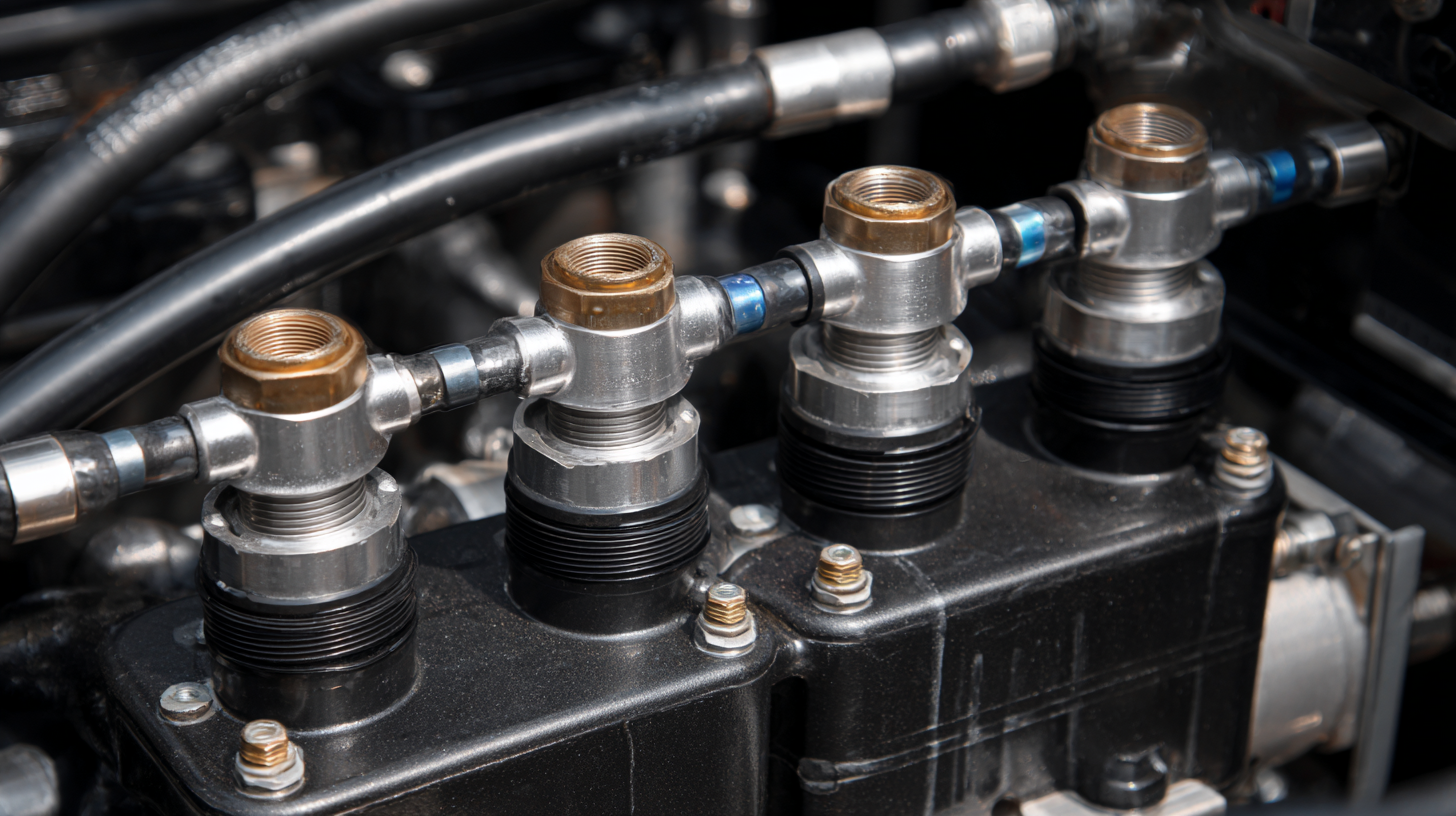

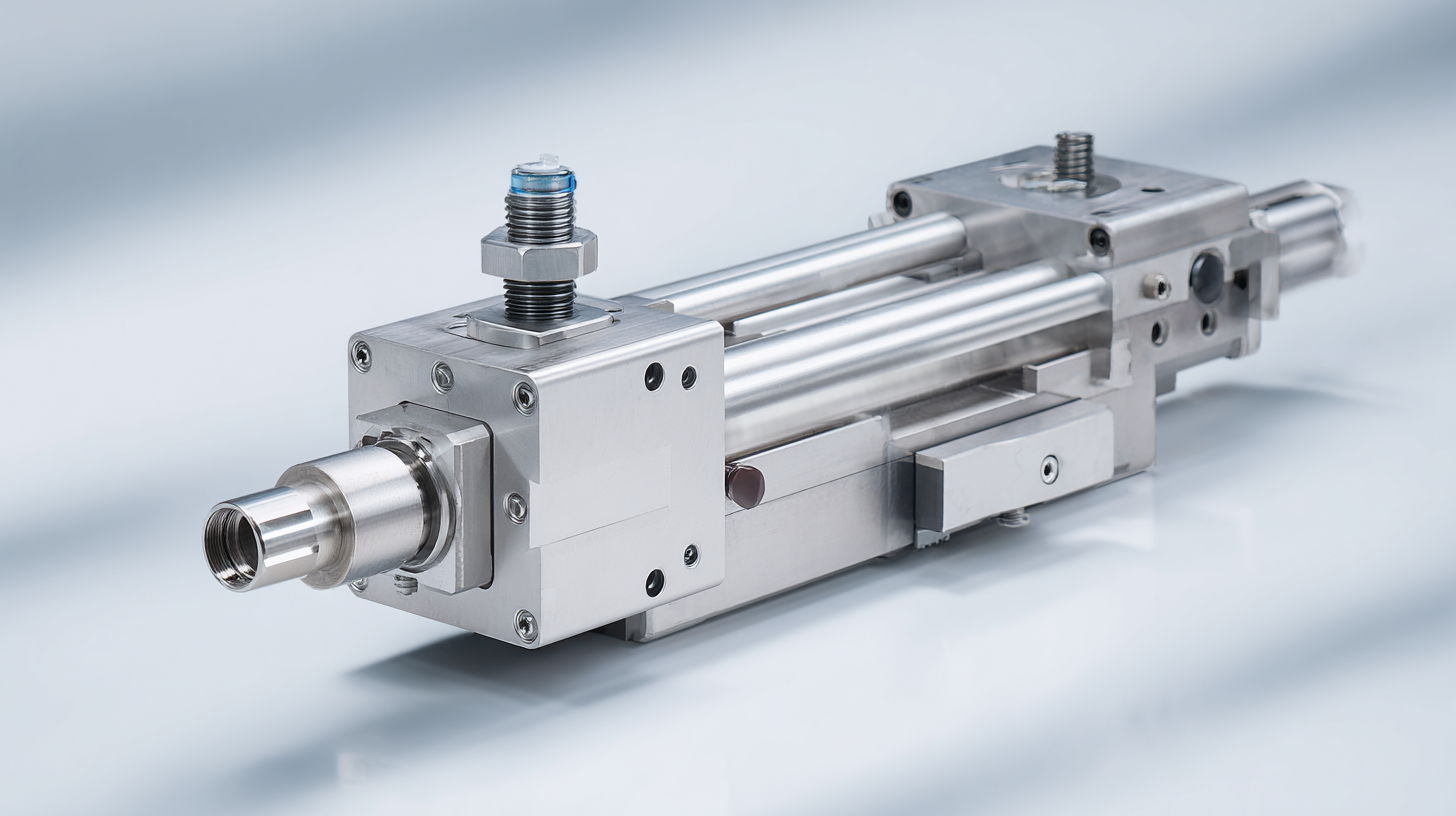

In the rapidly evolving landscape of pneumatic components, the year 2024 marks a significant milestone, with the global market projected to reach a staggering value of $4.5 billion. This remarkable growth is driven by the relentless pursuit of efficiency and performance in various industrial applications. Engineered in China, high-performance pneumatic parts are at the forefront of this transformation, designed to meet the increasing demands of modern manufacturing processes.

Key features of these advanced pneumatic components include enhanced durability, precision engineering, and adaptability to various operational requirements. The integration of smart elements within the industrial framework, particularly in the era of Industry 4.0 and AIoT, allows for improved real-time monitoring and data collection, optimizing performance and facilitating low-carbon manufacturing practices. As China continues to innovate and lead in this domain, the focus remains on providing unmatched performance through high-quality, reliable products that not only meet but exceed industry standards. This evolution in pneumatic technology underscores the commitment to driving forward the future of manufacturing excellence.

Quality Assurance Practices in Chinese Manufacturing

In recent years, Chinese manufacturing has made significant strides in quality assurance practices, particularly in the production of pneumatic parts. According to a report by McKinsey & Company, over 70% of manufacturers in China have adopted advanced quality management systems (QMS) to enhance their operational efficiency. This shift has been instrumental in increasing the reliability and performance of pneumatic components, which are critical in various industries, from automotive to aerospace.

Implementing a robust QMS involves rigorous testing and compliance with international standards such as ISO 9001. Manufacturers are increasingly utilizing digital tools, including Artificial Intelligence (AI) and the Internet of Things (IoT), to monitor production processes in real-time. These technologies not only help in identifying defects early but also facilitate continuous improvements in product quality.

Tips: To ensure you're sourcing high-quality pneumatic parts from China, look for manufacturers that have certifications like ISO 9001 and regularly publish their quality metrics. Additionally, it's beneficial to request samples and performance reports before placing a large order to evaluate the product consistency firsthand. Engaging with suppliers who are transparent about their quality assurance processes can further assure you of their commitment to excellence.

Innovative Technologies Driving Pneumatic Solutions

Innovative technologies are revolutionizing the pneumatic parts industry, particularly in China, which has become a global leader in this sector. According to a report by Research and Markets, the global pneumatic components market is expected to reach $33 billion by 2025, driven by advancements in automation and the increasing demand for efficient manufacturing processes. China's strategic investments in R&D and state-of-the-art manufacturing facilities have enabled local companies to deliver high-performance pneumatic solutions that meet international standards.

For manufacturers looking to enhance their pneumatic systems, it’s essential to consider incorporating smart technologies such as IoT-enabled sensors and predictive maintenance tools. These innovations not only improve operational efficiency but also significantly reduce downtime. Additionally, utilizing lightweight materials in the design of pneumatic components can yield substantial energy savings and enhance overall system performance.

Tip: Regularly assess your pneumatic systems to identify opportunities for upgrades. Leveraging technology such as automation and data analytics can optimize your processes and contribute to long-term savings. Remember, in an ever-evolving market, staying ahead with innovative solutions can set your operations apart from the competition.

Global Market Impact: Chinese Pneumatic Parts on the Rise

The pneumatic parts industry has witnessed a significant transformation in recent years, with Chinese manufacturers leading the charge towards global excellence. As production capabilities evolve, these companies are not only improving the quality of their products but also adopting advanced technologies. This shift has allowed Chinese pneumatic parts to gain traction in global markets, providing robust solutions for various industries including automotive, manufacturing, and robotics.

The rising influence of Chinese pneumatic parts can be attributed to several factors. Competitive pricing, coupled with a focus on innovation and efficiency, has enabled these products to meet international standards while remaining accessible to a wide range of customers. Moreover, China's strategic investment in research and development is fostering the emergence of high-performance pneumatic components that cater to specialized applications. As a result, industries around the world are beginning to recognize and rely on the unmatched performance of these engineered products, further solidifying China's position as a crucial player in the global market for pneumatic parts.