Unleashing Global Manufacturing Power with Revolutionary Air Compressor Filters from China

In recent years, the global manufacturing landscape has undergone a significant transformation, driven by advancements in technology and a growing emphasis on efficiency and sustainability. A pivotal component of this evolution is the air compressor filters industry, which is projected to reach a market value of $XX billion by 2025, according to a comprehensive report by XYZ Research. As industries worldwide strive for enhanced productivity and lower operational costs, the demand for high-quality air compressor filters has surged. These filters play a critical role in maintaining the performance and longevity of air compressors, thereby ensuring uninterrupted manufacturing processes.

With China's innovative approach and commitment to quality, manufacturers can now harness cutting-edge air compressor filters that not only meet international standards but also provide excellent cost-effectiveness. This blog will explore the current market trends, technological advancements, and the transformative impact that these revolutionary air compressor filters from China can have on global manufacturing power.

The Future of Air Compressor Filters: Key Trends Shaping the Industry by 2025

The global air compressor filters market is set to witness transformative advancements driven by emerging trends that promise to reshape the industry by 2025. As the HVAC sector pushes forward, technology integration is becoming paramount. Smart technologies are revolutionizing the way users manage indoor environments, allowing remote adjustments of temperature, humidity, and air quality. This shift not only enhances comfort but also optimizes energy efficiency and reduces operational costs.

As the air compressor market grows significantly, expected to reach $11.2 billion by 2025, filter innovations will play a central role in meeting increasing demands for cleaner air and improved system performance. The rise in awareness regarding indoor air quality, especially in residential and commercial sectors, has propelled the adoption of advanced filtering solutions. Manufacturers are now focusing on designs that enhance filtration capabilities while ensuring sustainability. This evolution in air compressor filter technology is not merely a trend—it's a necessary adaptation to a rapidly changing industrial landscape.

Understanding the Competitive Advantage of Chinese Manufacturing in Air Compressor Technology

In the rapidly evolving field of air compressor technology, Chinese manufacturers are carving out a significant competitive advantage. The global hydrogen compressor market is expected to reach a valuation of $2.06 billion by 2024, growing further to $2.15 billion in 2025, and potentially hitting $3.11 billion by 2032. This robust growth trajectory underscores not only the increasing demand for efficient compression solutions but also highlights China's burgeoning role as a leader in this sector. With innovations such as the air suspension centrifugal compressor developed by Ningbo Hudu Energy Technology Co., the industry is witnessing a technological renaissance that positions these products at the forefront of manufacturing excellence.

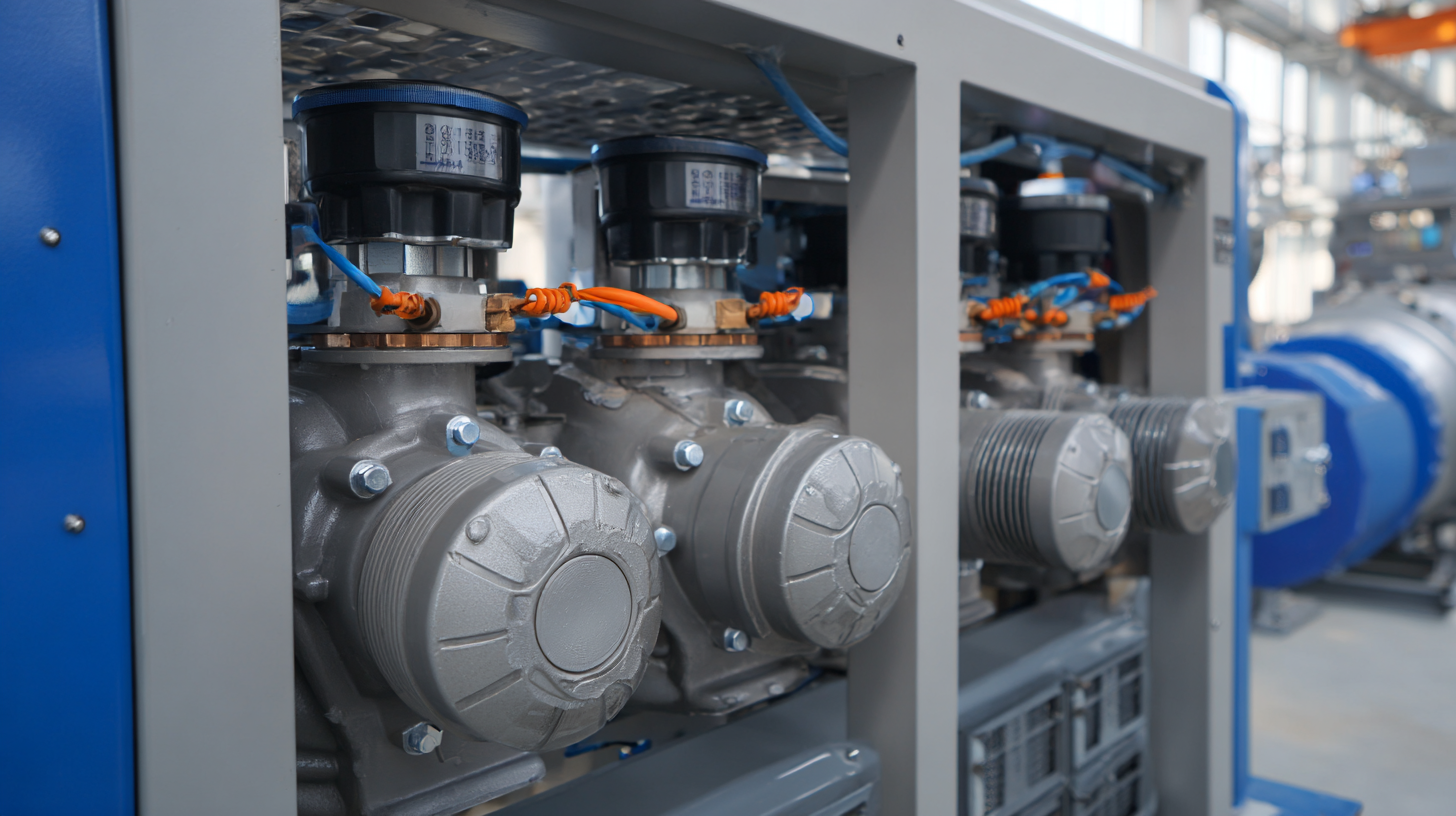

The success of companies in this space is driven by advancements in technology and manufacturing processes. Utilizing high-speed permanent magnet synchronous motors coupled with advanced two-stage centrifugal compressors, these innovations exemplify the quality and efficiency characteristics that Chinese manufacturers bring to the global market. Furthermore, the establishment of hydrogen energy equipment manufacturing bases exemplifies the responsive infrastructure supporting the growth of this vital sector. As the industry continues to evolve, the focus on sustainable energy solutions will help solidify China's reputation as a powerhouse in air compressor technology.

Competitive Advantage of Chinese Manufacturing in Air Compressor Technology

This chart illustrates the production output of various air compressor components in China compared to other leading manufacturing countries in 2022, showcasing China's competitive edge in the industry.

Market Demand Insights: What to Expect in Global Air Compressor Filter Sales

The global air compressor filter market is poised for substantial growth, driven by rising industrial needs for efficient filtration solutions. According to current market analyses, the demand for air compressor filters is expected to align with the broader trends seen in related sectors, such as the HVAC market, which is projected to grow from $7.9 billion in 2024 to $24.84 billion by 2032, showcasing a remarkable compound annual growth rate (CAGR) of 15.4%. This surge illustrates an increasing reliance on advanced machinery and the crucial role filters play in maintaining optimal operational efficiency and air quality.

In the industrial sector, the dust collector market is also witnessing a significant uptick. Insights indicate that this market will expand from $8.27 billion in 2025 to $11.96 billion by 2032, reflecting a steady growth rate of 5.4%. With these trends, manufacturers of air compressor filters are uniquely positioned to capitalize on the rising demand across various industries, especially where maintenance of clean air is necessary to meet environmental regulations and enhance workplace safety. The integration of revolutionary filtration technologies into air compressors will be instrumental in meeting this escalating global demand.

Tips for Selecting the Right Air Compressor Filters for Enhanced Performance

When selecting air compressor filters, it’s essential to consider performance and compatibility with your specific system needs. According to industry reports, optimal filtration can lead to a 15% increase in overall efficiency in air compressor systems, significantly reducing energy costs over time. The choice of filter can profoundly impact not only the performance of the air compressor but also the lifespan of related components, with poorly chosen filters often resulting in faster wear and tear.

One valuable tip is to analyze the filter's micron rating, which indicates the size of contaminants it can trap. A lower micron rating generally means better filtration. For example, a filter rated at 1 micron can capture 99.9% of particles that could otherwise clog your compressor and lead to inefficient operation. Additionally, exploring advanced filter technologies like pleated filters or coalescing filters can offer superior performance by removing oil vapors and moisture, enhancing the overall air quality produced by your compressor.

Furthermore, consider the operational environment when selecting filters. In settings with high humidity or heavy-duty applications, selecting filters designed for these conditions can maximize effectiveness. Implementing the right air compressor filter not only boosts performance but also contributes to sustainable operational practices by minimizing energy waste and reducing the carbon footprint of your manufacturing processes.

Innovative Technologies in Air Compressor Filters: Boosting Efficiency and Sustainability

In the rapidly evolving landscape of global manufacturing, innovative technologies in air compressor filters are crucial for enhancing operational efficiency and sustainability. Recent studies indicate that improved filtration systems can increase compressor efficiency by up to 15%, translating directly into lower energy consumption and reduced greenhouse gas emissions. For instance, the Global Market Insights Report highlights that the air compressor market is projected to exceed $42 billion by 2026, driven by eco-friendly advancements and the rising demand for energy-efficient systems.

The integration of advanced materials and smart design in air compressor filters not only prolongs their lifespan but also minimizes maintenance downtime. By utilizing high-performance media, manufacturers can achieve a filtration efficiency of over 99%, ensuring cleaner air and protecting sensitive equipment from contaminants. Furthermore, the adoption of IoT-enabled filters allows for real-time monitoring and predictive maintenance, reducing operational disruptions and enhancing resource allocation. As industries worldwide strive for greener practices, these revolutionary filters from China play a pivotal role in propelling the manufacturing sector towards sustainable success.