Ultimate Guide to Choosing the Best Piston Compressor for Your Needs

When it comes to selecting the ideal piston compressor for your specific applications, understanding the various types and features available is crucial. Piston compressors are renowned for their durability and efficiency, making them a popular choice in diverse industries ranging from automotive to manufacturing. However, with countless options on the market, choosing the best piston compressor can be a daunting task.

This comprehensive guide aims to simplify the decision-making process by providing insights into the different types of piston compressors, their operational principles, and key factors to consider based on your needs. Whether you require a compressor for light-duty tasks or heavy industrial use, our solutions will help you navigate the complexities and ultimately select a piston compressor that best meets your requirements.

Understanding Piston Compressors: Types and Applications

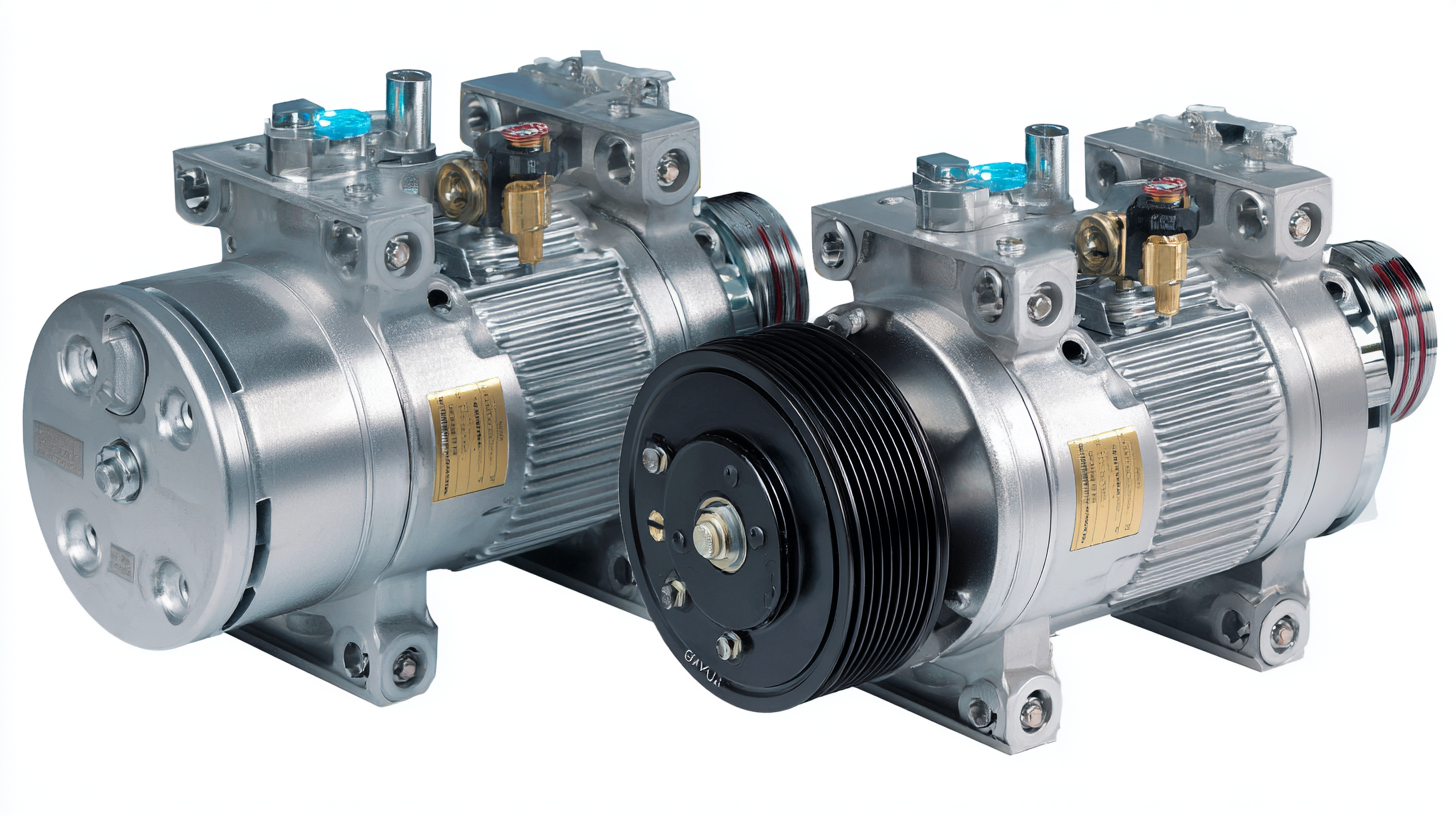

Piston compressors are an integral part of various industrial applications, and understanding their types can significantly enhance efficiency and performance. The primary types of piston compressors include single-stage and two-stage models.

Single-stage compressors are ideal for tasks requiring lower pressure levels, such as inflating tires or powering pneumatic tools. These compressors utilize a single-cylinder mechanism, making them compact and easy to maintain, perfect for smaller jobs or home use.

In contrast, two-stage piston compressors are designed for high-pressure applications, such as in manufacturing or heavy machinery. They feature two cylinders: the first compresses the air to an intermediate pressure, and the second further compresses it to the desired high pressure.

This design not only increases efficiency but also extends equipment lifespan by reducing the heat generated during compression. Understanding the strengths and suitable applications of each type can help users choose the right piston compressor for their specific needs, ensuring optimal performance and productivity in their operations.

Key Factors to Consider When Choosing a Piston Compressor

When selecting the best piston compressor for your needs, several key factors play a crucial role in the decision-making process.

First and foremost, you should consider the compressor's application. For instance, according to the Compressed Air and Gas Institute, the demand for piston compressors has surged in industries such as automotive and manufacturing, primarily due to their efficiency and reliability in high-pressure applications. It is vital to match the compressor's specifications with your specific requirements, including pressure output and air volume.

First and foremost, you should consider the compressor's application. For instance, according to the Compressed Air and Gas Institute, the demand for piston compressors has surged in industries such as automotive and manufacturing, primarily due to their efficiency and reliability in high-pressure applications. It is vital to match the compressor's specifications with your specific requirements, including pressure output and air volume.

Another important aspect is the power source. Piston compressors are available in both electric and gasoline-powered options. A report by Freedonia Group indicates that electric compressors have become increasingly popular due to their lower operational costs and reduced noise levels. However, for remote or outdoor applications, a gas-powered model may be more suitable. When making your selection, evaluate your primary usage scenarios to determine which power source best meets your operational needs.

Tips: Always assess the duty cycle of the piston compressor; a unit designed for continuous usage may be more suitable for industrial settings, while lighter-use models are ideal for hobbyists or smaller workshops. Additionally, consider the compressor’s maintenance requirements; some models necessitate more frequent service, which can impact long-term costs and downtime. Finally, analyze the warranty and support offered by manufacturers to ensure you have access to assistance if needed.

Navigating Import and Export Certifications for Compressors

When considering the purchase of a piston compressor, understanding import and export certifications is crucial for ensuring compliance and safety. Many countries have specific regulations that dictate how compressors are manufactured, tested, and imported. Familiarizing yourself with these certifications not only helps you avoid legal complications but also ensures that you are purchasing a product that meets industry standards. Look for certifications such as ISO, CE, and ASME, which indicate that the compressor has undergone rigorous testing and adheres to required specifications.

Moreover, import certifications can affect the overall cost and availability of piston compressors. Some certifications may require additional documentation, inspections, or duties, which can influence shipping times and import costs. As such, it is essential to consult with suppliers and understand the certifications necessary for your location and intended use. By navigating these import and export requirements effectively, you can streamline the purchasing process and ensure that you invest in a piston compressor that is both efficient and compliant with the legal standards.

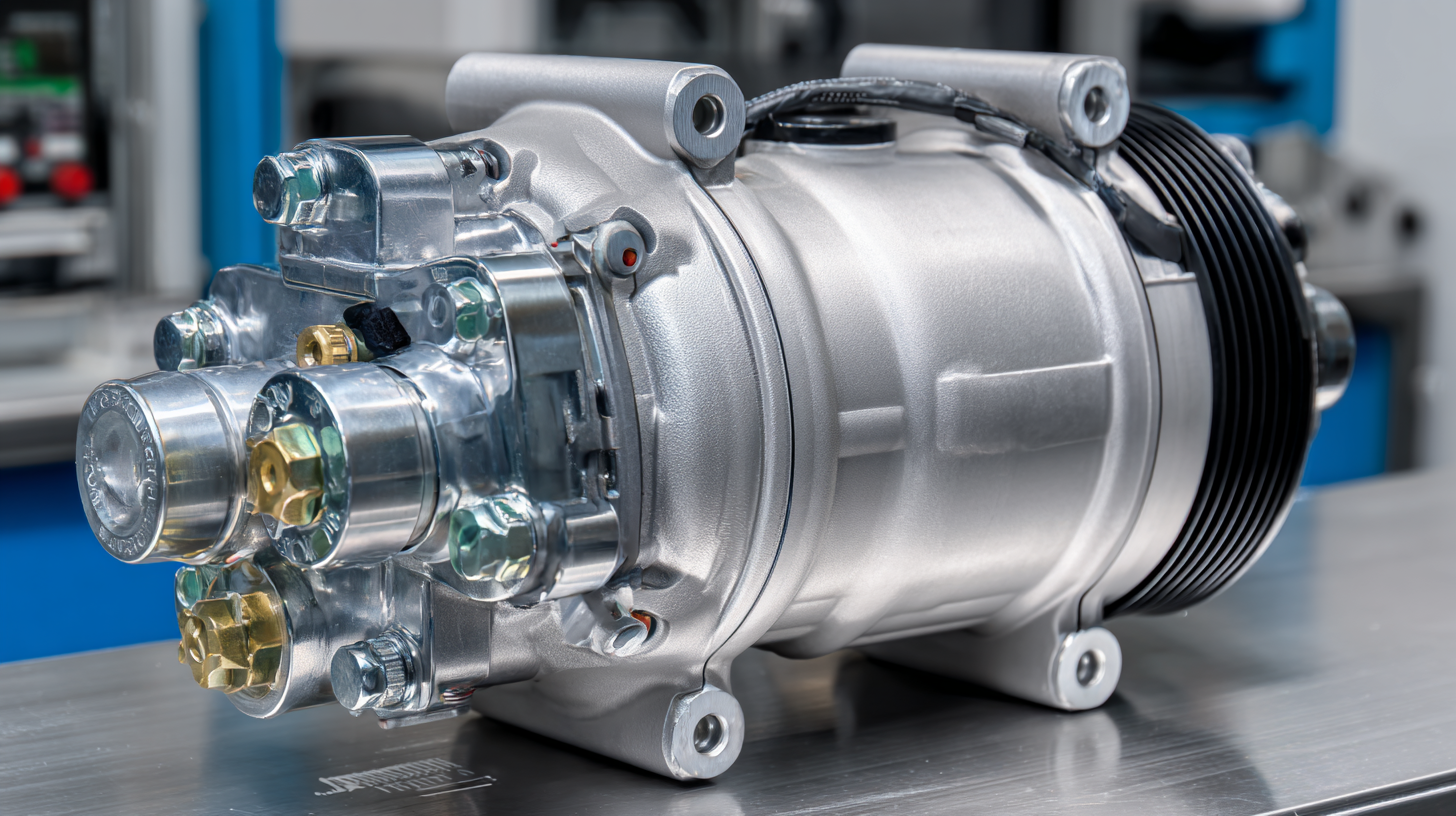

Maintenance Tips to Ensure Optimal Performance of Your Piston Compressor

When it comes to maintaining the optimal performance of your piston compressor, regular upkeep is crucial. According to a report from the Compressed Air and Gas Institute (CAGI), proper maintenance can enhance the efficiency of your compressor by up to 30%. One of the most critical elements is regular oil changes, as lubricants degrade over time, leading to increased wear and reduced efficiency. It is recommended to change the oil every 500-1000 operating hours, depending on usage and manufacturer specifications.

In addition to oil maintenance, attention should be given to air filters and intake components. A clogged air filter can restrict airflow, causing the compressor to work harder, which can lead to overheating and premature failure. CAGI’s data suggests that replacing or cleaning filters according to the manufacturer's guidelines can reduce energy consumption significantly—by as much as 10%. Furthermore, routine inspections of belts and valves will ensure that any issues are identified early, preventing costly breakdowns. By prioritizing these maintenance practices, users can ensure their piston compressors operate efficiently and reliably for years to come.

Maximizing Efficiency: How to Select the Right Piston Compressor Size

Selecting the right size of a piston compressor is crucial for maximizing efficiency and ensuring optimal performance. When choosing a piston compressor, consider the specific applications you need it for. A compressor that is too small will struggle to meet your demands, leading to increased wear and inefficiency. Conversely, an oversized compressor can waste energy and may not be cost-effective.

**Tip:** Calculate the required airflow in cubic feet per minute (CFM) based on your tools and equipment. This will help you identify a compressor that meets your needs without being unnecessarily large.

Additionally, consider the duty cycle of your compressor. This refers to the amount of time the compressor can run before needing a break. For continuous operations, a larger tank size may be necessary to avoid frequent cycling.

**Tip:** Choose a compressor with a tank that provides ample air storage for your usage patterns. If your tools require a steady flow of air for extended periods, a larger tank will help maintain pressure without the motor frequently turning on and off, thereby enhancing the longevity of the compressor.

Ultimate Guide to Choosing the Best Piston Compressor for Your Needs

| Application | Required PSI | Required CFM | Tank Size (Gallons) | Power Source |

|---|---|---|---|---|

| HVAC Service | 90 PSI | 10 CFM | 30 Gallons | Electric |

| Auto Repair | 100 PSI | 15 CFM | 60 Gallons | Gas |

| Construction | 120 PSI | 20 CFM | 80 Gallons | Electric |

| Manufacturing | 150 PSI | 25 CFM | 120 Gallons | Electric |

| Woodworking | 80 PSI | 6 CFM | 15 Gallons | Electric |