The Ultimate Guide to Selecting the Best Compressor Pumps: Industry Insights and Expert Tips

In the realm of industrial applications, compressor pumps play a pivotal role in enhancing efficiency and productivity across various sectors. According to a recent report by the International Energy Agency, the industrial sector contributes nearly one-third of global energy consumption, with compressor systems accounting for a significant portion of this demand. Selecting the right compressor pump is critical, as the types and applications vary widely, each boasting unique features tailored for specific operational needs. For instance, rotary screw compressors are praised for their continuous operation and efficiency, while reciprocating compressors excel in high-pressure applications. Understanding the distinctions among these products and knowing their appropriate use cases is essential for businesses aiming to optimize performance and reduce operational costs. In this comprehensive guide, we delve into the intricacies of selecting the best compressor pumps, providing industry insights and expert tips that empower users to make informed decisions.

Key Factors to Consider When Choosing Compressor Pumps for Your Needs

When selecting the best compressor pumps, it's essential to consider several key factors that will ensure the chosen pump meets your specific needs. First and foremost, assess the required pressure and flow rate for your applications. Different tasks demand varying levels of performance, so understanding the operational requirements will guide you in selecting the right pump type, whether it be reciprocating, rotary screw, or diaphragm. Additionally, the size and capacity of the pump should align with the space available for installation and the overall operational efficiency desired.

Another critical aspect to consider is the environment in which the compressor pump will be used. Factors such as temperature, humidity, and exposure to contaminants can significantly impact the pump's reliability and lifespan. For example, certain pumps are better suited for harsh environments and can withstand varying temperatures, while others may require additional protective measures. Furthermore, evaluating the maintenance requirements and the availability of replacement parts can save time and costs in the long run. By focusing on these key factors, you can make an informed decision that enhances productivity and ensures the longevity of your compressor pump.

Understanding the Different Types of Compressor Pumps and Their Applications

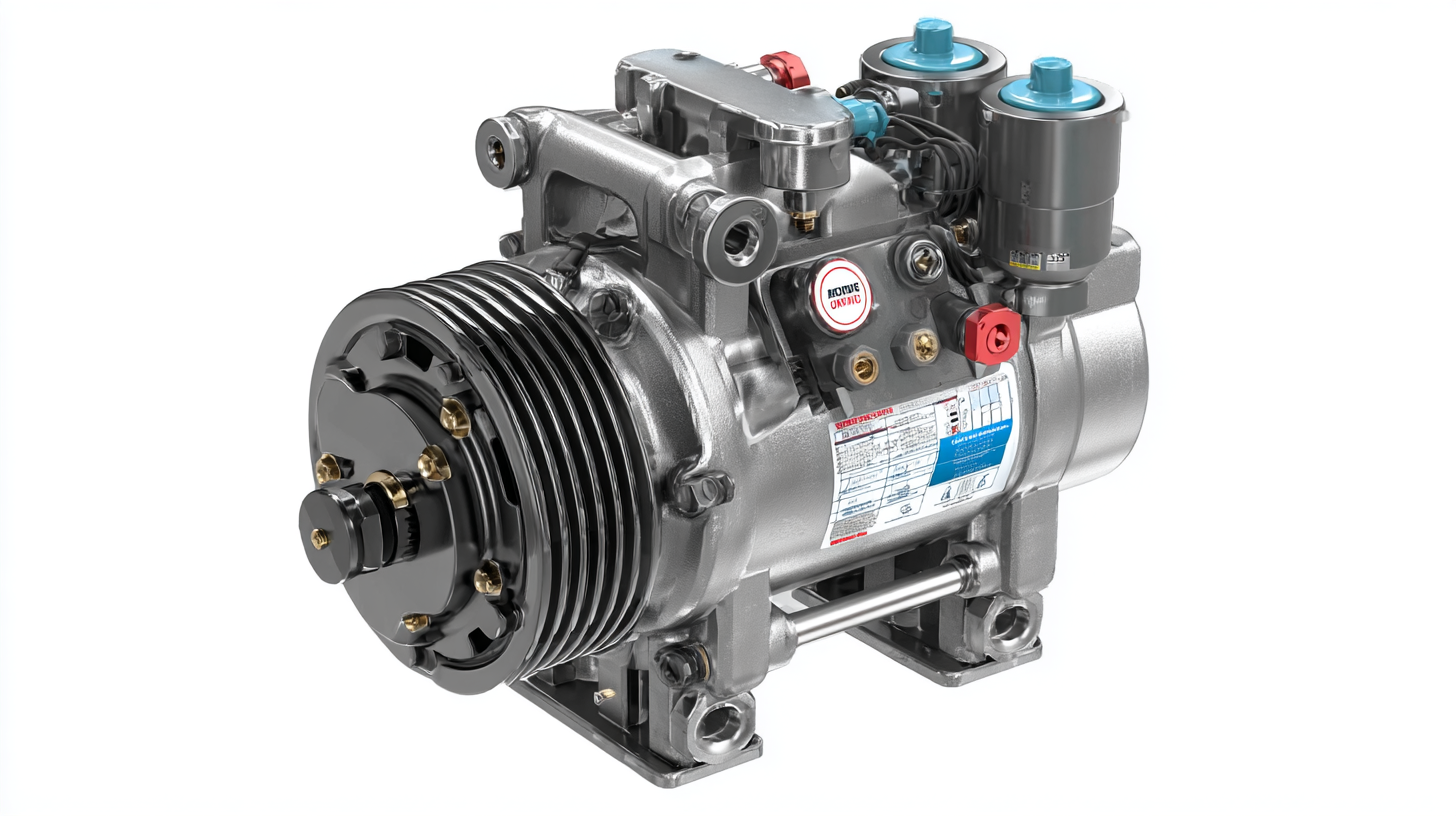

When it comes to selecting the best compressor pumps, understanding the various types and their applications is crucial for optimal performance. Compressor pumps can fundamentally be categorized into positive displacement and dynamic compressors. Positive displacement pumps, which include piston, diaphragm, and rotary screw designs, work by trapping a fixed volume of air and then forcing it into a smaller space, making them ideal for high-pressure applications. They are widely used in industries requiring substantial power, such as manufacturing and automotive.

On the other hand, dynamic compressors, including centrifugal and axial compressors, generate airflow by imparting kinetic energy to the air through rotating blades, making them suitable for applications involving large volumes of air at lower pressures. These are often found in HVAC systems and gas transport, where efficiency and constant airflow are paramount. By understanding these differences, users can better evaluate their specific needs and select a compressor pump that not only fits their application but also optimizes energy usage and performance in their operations.

The Ultimate Guide to Selecting the Best Compressor Pumps: Industry Insights and Expert Tips

| Type of Compressor Pump | Application | Key Features | Optimal Industries |

|---|---|---|---|

| Reciprocating Compressor | Air Pressure Systems | High pressure, Efficient at low flow | Manufacturing, Construction |

| Rotary Screw Compressor | Continuous Air Supply | Low noise, High volume capacity | Automotive, Food & Beverage |

| Scroll Compressor | HVAC Systems | Compact design, Quiet operation | Residential, Commercial |

| Centrifugal Compressor | Large Volume Air Handling | High flow rates, Energy efficient | Power Plants, Oil & Gas |

| Diaphragm Compressor | Chemical Applications | Leak-free, Handles corrosive gases | Chemical, Pharmaceutical |

Essential Features That Enhance Efficiency and Performance in Compressor Pumps

When selecting compressor pumps, understanding the essential features that enhance efficiency and performance is crucial for optimal operation. One of the primary factors to consider is the pump’s flow rate. A higher flow rate ensures that air or fluid is delivered efficiently, reducing downtime and improving overall productivity. Additionally, look for pumps equipped with adjustable speed settings. This feature allows users to tailor performance to specific needs, further maximizing energy usage and minimizing waste.

Another critical aspect is the build quality of the compressor pump. Materials that withstand wear and corrosion, such as aluminum or high-grade steel, contribute to longevity and reliability. Moreover, an efficient cooling system is vital for maintaining optimal operating temperatures, which prevents overheating and prolongs the life of the pump. Noise levels, often overlooked, are also significant; quieter models enhance the working environment while still delivering high performance. By focusing on these essential features, users can select compressor pumps that not only meet their current needs but also adapt to future demands.

The Ultimate Guide to Selecting the Best Compressor Pumps

Expert Tips for Maintaining and Troubleshooting Your Compressor Pump

When it comes to maintaining compressor pumps, experts emphasize the importance of routine checks to ensure efficient operation. Regularly inspecting your compressor pump can prevent costly breakdowns and extend its lifespan. One essential tip is to always keep the pump clean from dust and debris. This simple task helps avoid overheating and operational inefficiencies that might occur from accumulated grime.

Additionally, monitoring the oil levels in your compressor pump is crucial. Adequate lubrication minimizes friction, which can lead to wear and tear on the components. It's advisable to check the oil regularly and replace it according to the manufacturer’s recommendations for optimal performance.

Lastly, if you notice any unusual sounds or vibrations during operation, don't ignore them. These could be signs of deeper issues that may require professional attention. Regular troubleshooting and prompt intervention can save you from unexpected failures and ensure your compressor pump continues to function smoothly.

Cost-Effectiveness: Balancing Price and Quality in Compressor Pump Selection

When selecting the best compressor pumps, cost-effectiveness becomes a pivotal factor. The balance between price and quality can significantly influence performance and longevity. Choosing a compressor that is too cheap may lead to increased maintenance costs and reduced efficiency, ultimately negating any initial savings. Therefore, it is crucial to analyze not just the upfront price but also the long-term value that a high-quality compressor pump provides. Investing in a reputable brand with a proven reliability record pays off, especially when evaluating energy efficiency—an increasingly important consideration in today's environmentally conscious market.

Furthermore, with the rise of energy storage systems and sustainable practices, understanding the operational costs associated with compressor pumps is essential. Compressors that utilize advanced technologies may have higher initial costs, but their efficiency and effectiveness in energy usage can lead to substantial savings over time. As energy transmission costs fluctuate, selecting compressors that can operate efficiently can help businesses remain competitive and responsive to market demands. By prioritizing quality and energy efficiency, users can ensure they are making a sound investment that benefits both the environment and their bottom line.