What Are Industrial Parts? A Comprehensive Guide to Their Types and Uses

In the realm of manufacturing and production, the term "industrial parts" encompasses a vast array of components that are essential for the functioning of machinery and equipment across various industries. These parts serve as the building blocks of complex systems, ensuring seamless operations within industrial settings. Understanding the different types of industrial parts, and their specific uses, is crucial for professionals in manufacturing, engineering, and maintenance fields, as it facilitates better decision-making when it comes to sourcing, replacing, or innovating on existing systems.

This comprehensive guide aims to shed light on the diverse classifications of industrial parts, ranging from fasteners and bearings to electronic components and hydraulic systems. Each category plays a vital role in ensuring the efficiency, safety, and reliability of industrial operations. By exploring the characteristics and functions of different industrial parts, stakeholders can enhance productivity, reduce downtime, and ultimately contribute to the success of their enterprises. Whether you are a seasoned engineer or someone new to the industrial sector, grasping the intricacies of industrial parts will empower you to navigate the complexities of modern manufacturing with confidence.

Understanding Industrial Parts: Definition and Importance

Industrial parts are essential components that play a crucial role in the manufacturing and functionality of various machinery and systems. These parts can include anything from gears, bearings, and valves to more specialized components like circuit boards or hydraulic systems. Understanding industrial parts is paramount for businesses aiming to optimize their operations and enhance efficiency. The importance of industrial parts extends beyond just their mechanical function; they are integral to maintaining the safety, reliability, and durability of equipment in various industries.

When selecting industrial parts, it’s vital to consider their specifications and compatibility with existing systems. Proper selection ensures that the machinery operates smoothly and reduces the risk of breakdowns. Failing to choose the correct components can lead to inefficiencies and costly downtime.

**Tip:** Always consult with technical manuals or professionals before making purchases to ensure compatibility with your existing machinery.

Additionally, maintaining an inventory of essential industrial parts can save time and reduce interruptions in production. Having quick access to commonly used parts allows for faster repairs and minimizes the risk of prolonged equipment failure.

**Tip:** Implement a regular review of your inventory levels to identify parts that need restocking before they run out.

Industrial Parts Usage by Sector

This chart illustrates the distribution of industrial parts usage across various sectors. Manufacturing leads the way, followed by Construction and Automotive. Each sector relies on specific industrial components that are critical to their operations.

Categories of Industrial Parts: An Overview

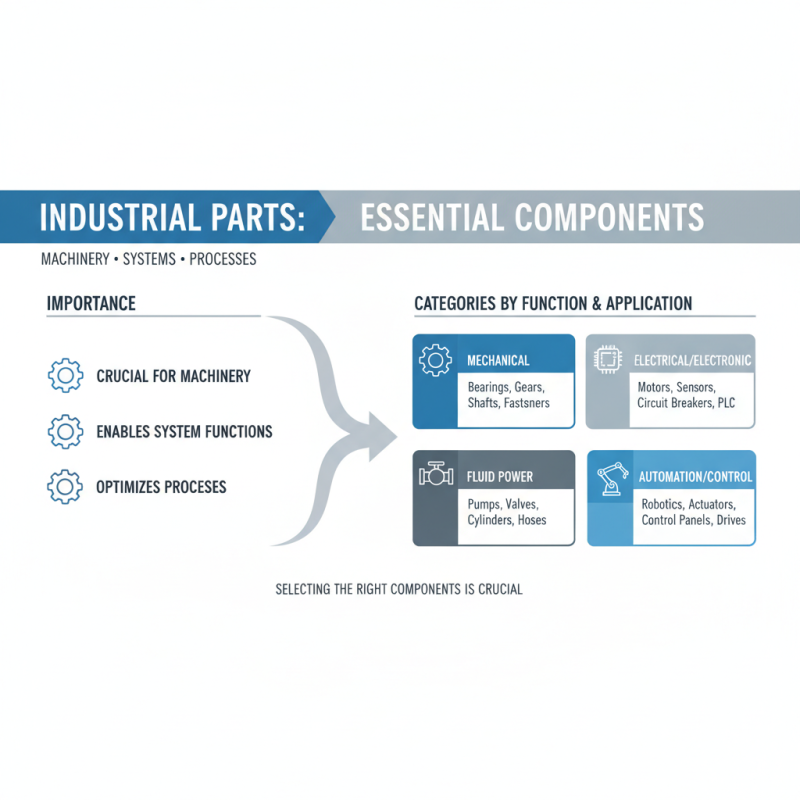

Industrial parts are essential components used in various machinery, systems, and processes across different sectors. They can be categorized into several types based on their functions and applications. Understanding these categories is crucial for selecting the right components for specific industrial needs.

One major category of industrial parts is **mechanical components**, which includes items such as gears, bearings, shafts, and fasteners. These parts are designed to support movement and transfer forces within machinery. Another important category is **electrical components**, encompassing motors, sensors, and switches, which are integral to controlling and facilitating electronic operations. Additionally, **fluid power components** like pumps and valves play a pivotal role in systems that utilize hydraulic or pneumatic power.

Beyond these, **structural components** such as frames, panels, and brackets provide necessary support and housing for various equipment. Furthermore, **consumable parts**, including filters and belts, require periodic replacement and maintenance to ensure optimal operation. Each category of industrial parts serves a unique function, making them indispensable in the realms of manufacturing, construction, and maintenance. Understanding the various types of industrial parts allows industries to operate efficiently and effectively.

Common Materials Used in Industrial Parts Manufacturing

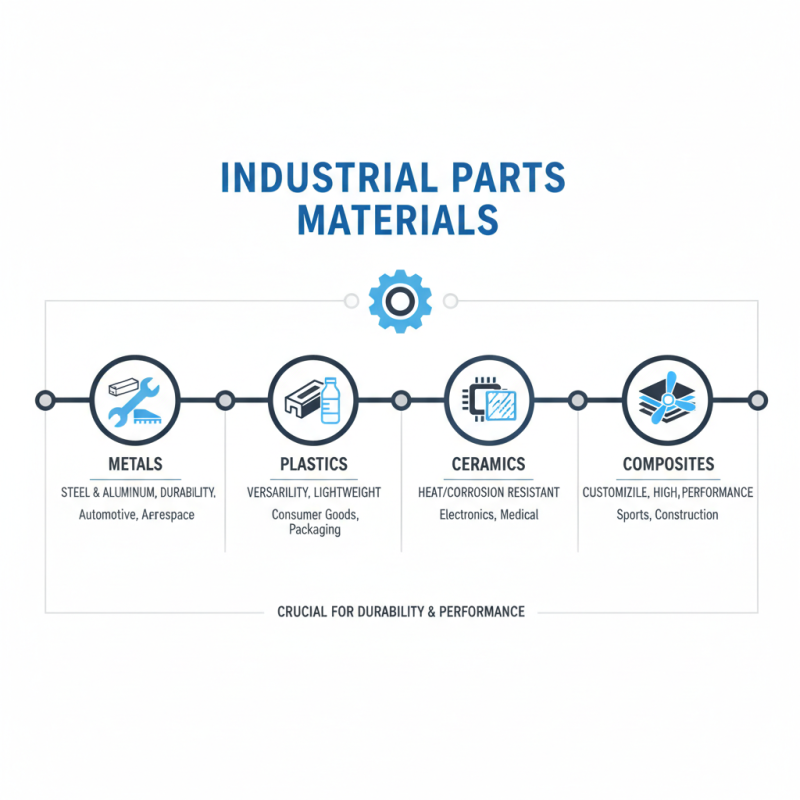

In the manufacturing of industrial parts, the choice of materials is crucial, as it directly affects the parts' durability, functionality, and performance. Commonly used materials include metals, plastics, ceramics, and composites. Metals such as steel and aluminum are favored for their strength and resistance to wear and tear, making them ideal for structural components, machinery parts, and tools. Steel’s high tensile strength and aluminum's lightweight properties allow for versatile applications across various industries, including automotive, aerospace, and heavy machinery.

Plastics, including polycarbonate and nylon, are increasingly popular due to their lightweight nature and corrosion resistance. They are often used in applications where weight reduction is essential while maintaining mechanical integrity, such as in automotive interiors and electronic housings. Ceramics provide exceptional hardness and thermal stability, making them suitable for high-temperature applications such as cutting tools and insulators. Lastly, composites, which combine different materials to achieve enhanced properties, are extensively used in aerospace applications where strength-to-weight ratio is critical.

Applications of Industrial Parts in Various Industries

Industrial parts play a crucial role across various sectors, serving essential functions that drive efficiency and productivity. In manufacturing, for example, components such as gears, bearings, and seals are pivotal in machinery operations. These parts facilitate movement and reduce friction, thereby enhancing the performance and longevity of equipment. Additionally, in the automotive industry, industrial parts like engine components and transmission systems are vital for vehicle reliability and safety. The intricate design and precision of these parts ensure that vehicles operate smoothly, meeting safety standards and consumer expectations.

In the construction sector, industrial parts contribute significantly to structural integrity and functionality. Steel beams, fasteners, and brackets are commonly used in building frameworks, ensuring stability and support for various structures. Moreover, in the energy sector, specialized parts are integral to the operation of turbines and generators, converting natural resources into usable energy. The adaptability of industrial parts allows them to cater to the specific demands of different industries, showcasing their versatility and importance in modern applications. Through innovation and continuous improvement in design, industrial parts remain indispensable tools for enhancing operational capabilities across diverse fields.

What Are Industrial Parts? A Comprehensive Guide to Their Types and Uses

| Type of Industrial Part | Material | Common Applications | Industry Sector |

|---|---|---|---|

| Gears | Steel, Plastic | Transmission of motion and torque | Automotive, Machinery |

| Bearings | Ceramic, Metal | Reducing friction in rotating applications | Manufacturing, Aerospace |

| Fasteners | Steel, Aluminum | Joining components together | Construction, Automotive |

| Pipes and Fittings | PVC, Copper | Transporting fluids and gases | Oil & Gas, Plumbing |

| Motors | Copper, Iron | Converting electrical energy into mechanical energy | Manufacturing, Robotics |

Future Trends in Industrial Parts and Technological Advancements

As industries evolve, the landscape of industrial parts is undergoing significant transformations driven by technological advancements. These changes are reshaping manufacturing processes, improving efficiency, and lowering operational costs. One major trend is the integration of smart technologies into industrial parts, allowing for real-time monitoring and predictive maintenance. This shift not only enhances the reliability of machinery but also minimizes downtime, a critical factor in competitive markets.

Tips: To stay ahead in this rapidly changing environment, organizations should invest in training programs that focus on the latest technologies in industrial components. Equipping employees with knowledge about smart sensors and IoT (Internet of Things) can lead to better implementation and utilization of these innovative tools.

Another noteworthy trend is the movement towards sustainability within the production of industrial parts. Companies are increasingly adopting eco-friendly materials and manufacturing processes to reduce their environmental impact. This not only meets customer demand for greener solutions but also complies with tightening regulations aimed at environmental protection. Emphasizing recyclability and energy efficiency in part design can significantly enhance a company's reputation and marketability.

Tips: Businesses should consider conducting regular audits to assess their sustainability practices. Engaging with suppliers who prioritize eco-friendly materials can further strengthen their commitment to sustainable practices, leading to a holistic approach that benefits both the business and the planet.

Related Posts

-

Top 10 Tips for Sourcing Quality Industrial Parts for Your Business

-

Unlocking Efficiency: The Advantages of Choosing Industrial Compressors for Your Business

-

Exploring Innovative Alternatives to Air Compressor Pumps for Efficient Performance

-

7 Essential Tips for Selecting the Best Scroll Air Compressor for Your Needs

-

2025 Top Rotary Air Compressors: Ultimate Guide to Choosing the Best

-

Ultimate Guide to Choosing the Best Piston Compressor for Your Needs