Top 10 Tips for Sourcing Quality Industrial Parts for Your Business

In the fast-paced world of manufacturing, the quality of industrial parts can significantly impact operational efficiency and product reliability. As highlighted by industry expert John Smith, a leading consultant in industrial procurement,

"Sourcing high-quality industrial parts is not just a preference; it's a necessity for maintaining competitiveness in today’s market."

In this regard, businesses must adopt strategic approaches to ensure they select components that meet both their quality standards and budgetary constraints.

With the ever-evolving technology landscape and market demands, businesses must stay ahead by leveraging best practices for sourcing industrial parts. This not only includes finding reliable suppliers but also involves understanding the specifications and materials that drive performance.

In this article, we will explore the top 10 tips for sourcing quality industrial parts, equipping businesses with the knowledge necessary to make informed decisions that bolster their production capabilities.

By investing time and resources into the sourcing process, companies can elevate their operational effectiveness and secure a sustainable advantage in their respective industries.

Identifying Reliable Suppliers for Industrial Parts Sourcing

When it comes to sourcing quality industrial parts, identifying reliable suppliers is paramount to ensuring the efficiency and longevity of your business operations. One effective approach is to conduct thorough research on potential suppliers. This includes assessing their industry reputation, customer reviews, and feedback. Engaging with industry forums or trade shows can provide insights into suppliers' reliability and help you establish connections with trusted entities.

Furthermore, it’s crucial to evaluate suppliers based on their production capabilities and quality control processes. Requesting samples and inspecting certifications, such as ISO standards, can help gauge their compliance with industry regulations. Establishing a clear line of communication with suppliers allows for ongoing dialogue, enabling you to discuss any concerns and ensure alignment with your specific needs. By prioritizing these steps, you can effectively identify suppliers who not only provide quality parts but are also committed to supporting your business in the long run.

Top 10 Tips for Sourcing Quality Industrial Parts for Your Business

| Tip No. | Tip | Description | Key Consideration |

|---|---|---|---|

| 1 | Research | Conduct thorough research on potential suppliers. | Check industry reviews and ratings. |

| 2 | Quality Standards | Ensure suppliers meet relevant quality standards. | Look for ISO certifications. |

| 3 | Communication | Establish clear communication channels. | Ensure quick response times. |

| 4 | Pricing | Compare pricing from different suppliers. | Watch out for hidden costs. |

| 5 | Lead Time | Inquire about lead times for production and delivery. | Balance lead time with quality. |

| 6 | Samples | Request samples before placing large orders. | Evaluate the quality of samples. |

| 7 | References | Ask for references from past clients. | Follow up for honest feedback. |

| 8 | Payment Terms | Understand the payment terms offered by suppliers. | Look for favorable terms. |

| 9 | Reliability | Assess the reliability and stability of suppliers. | Check history of on-time deliveries. |

| 10 | Long-term Partnership | Consider building long-term relationships with suppliers. | Review for benefits of collaboration. |

Evaluating Quality Standards and Certifications of Industrial Components

When sourcing quality industrial parts for your business, evaluating the quality standards and certifications of components is crucial. According to a report by MarketsandMarkets, the industrial automation market is projected to grow from $191.2 billion in 2021 to $274.9 billion by 2026, highlighting the increasing reliance on high-quality parts for efficient operations. Understanding and verifying certifications such as ISO 9001, which ensures consistent quality management systems, is essential for mitigating risks associated with component failure.

Furthermore, organizations like the International Electrotechnical Commission (IEC) provide important standards that help assess the reliability and safety of industrial parts. For instance, the IEC 61508 standard focuses on the functional safety of electrical, electronic, and programmable electronic safety-related systems. Adhering to these certifications not only assures compliance but also enhances the integrity of your supply chain. A study by the Quality Assurance Agency indicated that companies prioritizing certified components noticed a 20% reduction in operational downtimes due to improved part reliability. These insights emphasize that diligent evaluation of quality standards and certifications can lead to significant improvements in business performance.

Leveraging Technology for Efficient Parts Procurement Processes

In today's fast-paced industrial environment, leveraging technology in the procurement of quality parts has become essential for businesses aiming to enhance operational efficiency. Utilizing digital platforms and advanced software solutions can streamline the sourcing process, enabling companies to access a broader network of suppliers. By implementing procurement management systems, businesses can automate order processing, track inventory levels in real-time, and analyze market trends, ultimately reducing lead times and costs.

Moreover, integrating technologies like artificial intelligence and machine learning into sourcing strategies allows companies to predict demand more accurately and optimize their supply chain management. These tools can evaluate supplier performance based on historical data, ensuring that businesses partner with the most reliable sources for their industrial needs.

Additionally, utilizing online marketplaces and e-procurement platforms can foster transparency and competitive pricing, empowering businesses to make informed purchasing decisions while maintaining quality standards. The adoption of such technological advancements is vital for organizations looking to secure their supply chain and enhance their operational agility.

Building Strong Relationships with Manufacturers and Distributors

Building strong relationships with manufacturers and distributors is essential for sourcing quality industrial parts. First and foremost, effective communication is key. Establishing clear lines of communication ensures that both parties understand expectations, including deadlines, quality standards, and pricing. Regular check-ins and updates can help in resolving potential issues before they escalate, fostering a sense of collaboration that benefits both sides.

Moreover, it is crucial to invest time in understanding your partners' capabilities and limitations. Attending trade shows, factory visits, and conducting thorough assessments of their operations can deepen your insights into their production processes. This not only helps in building trust but also equips you with the knowledge needed to align your sourcing strategies better.

Strong relationships lead to more favorable terms, access to innovations, and the ability to respond swiftly to changing market demands. By prioritizing these connections, businesses can enhance their supply chain resilience and maintain a competitive edge in their industry.

Staying Informed on Market Trends and Innovations in Industrial Parts

Staying informed on market trends and innovations is vital for businesses sourcing quality industrial parts. As the industrial components market continues to grow, projected to reach a staggering $944.20 billion by 2030, understanding key developments becomes essential for strategic decision-making. Companies must focus on the evolving demands in the automotive sector, which is a critical pillar of the economy. With the rise of electric and smart vehicles, traditional components like wipers are transforming into sophisticated safety equipment, reflecting the industry's push towards innovation and sustainability.

Moreover, attending industry exhibitions, such as the upcoming 2026 International Auto Parts Expo in Wuhan, provides invaluable opportunities to connect with suppliers, discover new technologies, and stay ahead in this dynamic landscape. These events not only showcase the latest advancements but also help businesses network and gain insights that can drive growth. Keeping a pulse on these trends ensures that companies can effectively navigate the ever-changing market and source high-quality parts that meet evolving consumer expectations.

Related Posts

-

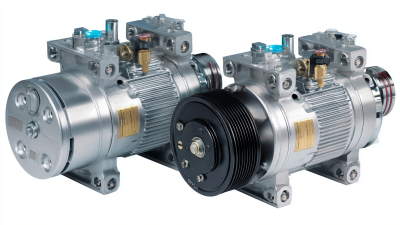

7 Essential Tips for Choosing the Right Air Compressors for Your Business

-

7 Essential Tips for Selecting the Best Scroll Air Compressor for Your Needs

-

Exploring Innovative Alternatives to Air Compressor Pumps for Efficient Performance

-

Unlocking the Power of Air Compressors: A Comprehensive Guide to Their Applications and Benefits

-

Ultimate Guide to Choosing the Best Piston Compressor for Your Needs

-

What is the Evolution of Air Pumps in Modern Industries and Their Impact on Efficiency