Superior Compressor Parts from China's Leading Factories Trust Built on Quality

In the competitive landscape of industrial manufacturing, the demand for high-quality compressor parts has seen significant growth. According to a report from MarketsandMarkets, the global compressor market is expected to reach USD 41.6 billion by 2025, driven by the rising need for energy-efficient systems across various sectors. As industries increasingly prioritize reliability and performance, sourcing compressor parts from trusted manufacturers has become paramount.

China, known for its extensive production capabilities and stringent quality controls, stands out as a leading provider in the market. However, buyers must navigate challenges regarding quality assurance and supplier trustworthiness. This blog will explore top strategies for identifying superior compressor parts from China's leading factories while ensuring that quality remains at the forefront of procurement decisions.

Characteristics of Different Types of Compressor Parts from Leading Chinese Factories

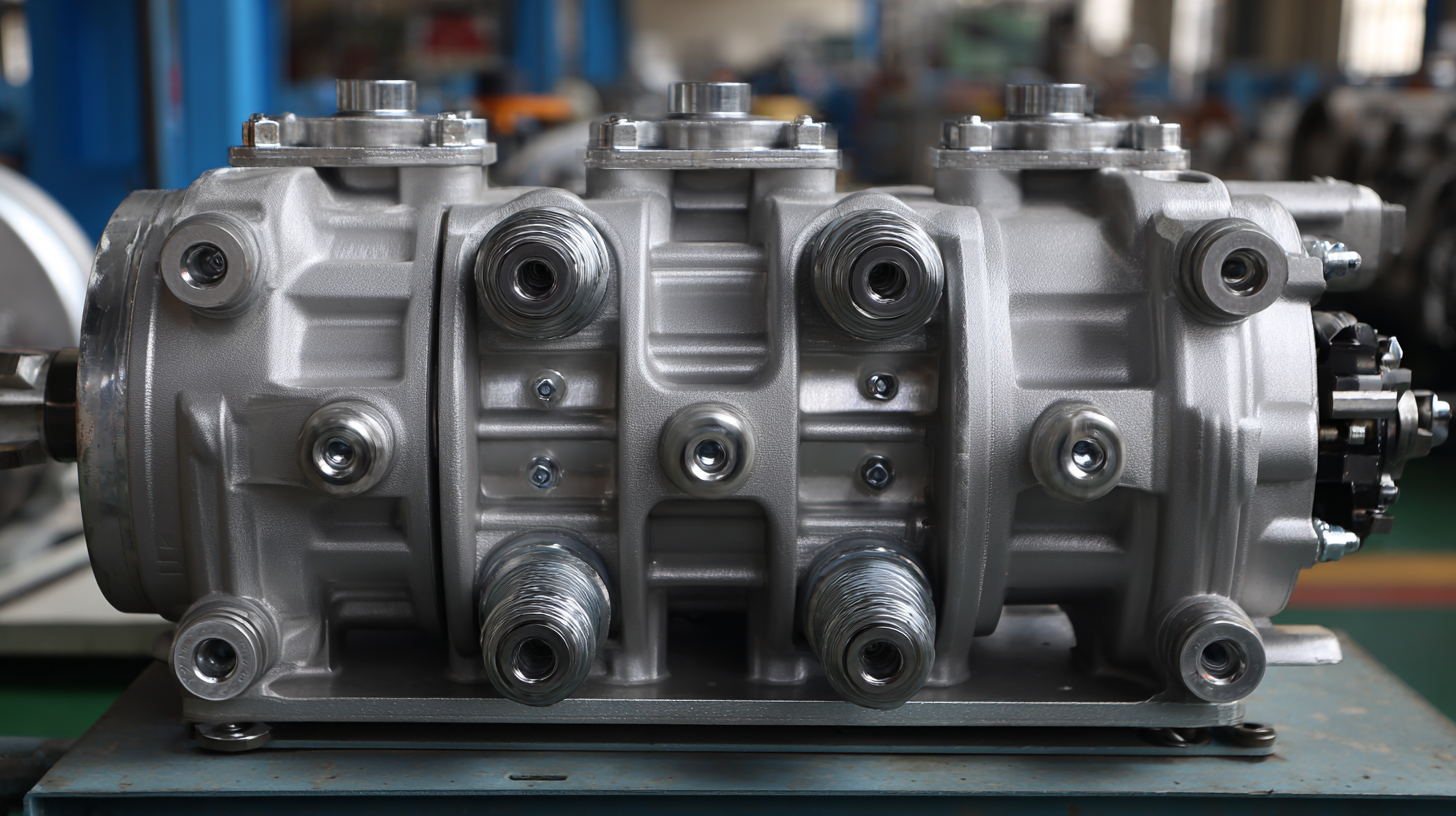

When it comes to compressor parts, the diversity in design and functionality is key to meeting various operational needs. Leading factories in China produce a wide range of components, each tailored for specific applications. For instance, piston rings are crafted from high-quality materials to ensure durability and effective sealing within the compression chamber. Their precision engineering minimizes wear and tear, resulting in increased efficiency and longevity of the compressor.

When it comes to compressor parts, the diversity in design and functionality is key to meeting various operational needs. Leading factories in China produce a wide range of components, each tailored for specific applications. For instance, piston rings are crafted from high-quality materials to ensure durability and effective sealing within the compression chamber. Their precision engineering minimizes wear and tear, resulting in increased efficiency and longevity of the compressor.

Another vital component is the compressor valve, which plays a crucial role in regulating airflow and pressure. Factories focus on advanced manufacturing techniques to create valves that offer quick response times and reliable operation under varying conditions. Additionally, rotor assemblies in rotary compressors utilize innovative designs that enhance performance and reduce noise levels, appealing to industries where sound reduction is critical. With a commitment to excellence, these manufacturers uphold stringent quality standards, ensuring that every part not only meets but exceeds industry requirements.

Applications of Compressor Parts in Various Industries and Their Benefits

Compressor parts play a crucial role across various industries, including manufacturing, HVAC, and oil and gas. According to a report by MarketsandMarkets, the global compressor market is expected to reach $40.52 billion by 2028, driven by the increasing demand for compressed air in industrial processes. High-quality compressor components ensure efficient operation, reduce energy consumption, and prolong the lifespan of machinery, making them indispensable for modern industries.

In the HVAC sector, for example, reliable compressor parts are essential for maintaining optimal efficiency and performance. The U.S. Department of Energy estimates that HVAC systems can account for up to 30% of a commercial building's energy consumption. By using superior compressor components designed for durability and efficiency, companies can significantly reduce their operational costs. Additionally, in the oil and gas industry, where compressors are integral in the transportation and processing of gas, the quality of parts directly impacts safety and productivity. As demand for these resources continues to climb, investing in top-tier compressor parts becomes increasingly vital for maintaining competitive advantage and operational reliability.

How to Choose the Right Compressor Parts for Your Needs

When selecting the right compressor parts for your needs, it's essential to consider a few critical factors. First, understanding the specific requirements of your compressor system is paramount. This includes knowing the type of compressor you have, whether it's a rotary screw, reciprocating, or centrifugal variant. Each type has unique components that play vital roles in their functionality, and mismatched parts can lead to inefficiency and increased wear. Additionally, consider the power output and capacity requirements, as this will impact the size and type of parts you need.

Quality should be a top priority when choosing compressor parts, especially when sourcing from international suppliers. Leading factories in China have developed strong reputations for their high-quality manufacturing practices and stringent quality control measures. Ensure that the parts you select meet internationally recognized standards and certifications. It’s also beneficial to seek out suppliers who offer comprehensive warranties and have a history of reliability. By prioritizing quality and compatibility, you can ensure that your compressor operates at peak efficiency, ultimately saving time and reducing costs over the life of your equipment.

Superior Compressor Parts from China's Leading Factories Trust Built on Quality - How to Choose the Right Compressor Parts for Your Needs

| Part Type | Material | Application | Quality Certification | Warranty Period | Price (USD) |

|---|---|---|---|---|---|

| Compressor Piston | Aluminum Alloy | Industrial Compressors | ISO 9001 | 12 Months | 150 |

| Compressor Valve | Cast Iron | Refrigeration Units | CE | 18 Months | 80 |

| Compressor Motor | Copper & Steel | HVAC Systems | ROHS | 24 Months | 300 |

| Compressor Filter | Synthetic Fiber | Air Compressors | SEDEX | 6 Months | 20 |

| Compressor Cylinder | Carbon Steel | Automotive Compressors | TS 16949 | 36 Months | 250 |

Innovative Manufacturing Processes in China's Compressor Parts Industry

In recent years, China's compressor parts industry has emerged as a leader in innovative manufacturing processes. This transformation is driven by advancements that enhance efficiency and quality while reducing environmental impacts. Manufacturers are increasingly adopting cutting-edge technologies and automation, allowing them to produce high-performance compressor components that meet the evolving demands of various industries, including automotive and energy.

Another key aspect of innovation in this sector is collaboration among manufacturers, tech firms, and research institutions. This synergy fosters the development of advanced compressor control systems and smart technologies, which are crucial in optimizing performance and reliability. When selecting compressor parts, consider companies that invest in R&D and partnerships, as they are more likely to offer innovative solutions that can enhance your operational efficiency.

Quality Assurance Measures for Superior Compressor Components from China

In today's competitive market, the quality of compressor components is paramount for the efficiency and longevity of industrial operations. China has emerged as a leader in the manufacturing of superior compressor parts, with its factories implementing rigorous quality assurance measures to ensure that every product meets international standards. These measures include comprehensive testing protocols, strict material selection processes, and adherence to global certifications, all designed to guarantee reliability and performance.

To maintain high-quality standards, leading Chinese manufacturers invest significantly in advanced technologies and skilled personnel. Automated inspection systems and real-time quality control procedures are employed throughout the production process to detect and rectify any potential issues before the components reach clients. Furthermore, ongoing training programs for factory workers are essential, equipping them with the latest knowledge and skills required to uphold the highest levels of craftsmanship. These investment efforts not only enhance product quality but also build strong, trust-based relationships with global customers seeking dependable compressor solutions.